Something strange happened...

It was just another day at work, and I had no idea that this was about to change. Easter Monday was just around the corner, and the anticipation of the coming long weekend was palpable throughout the workforce. I was about to grab a coffee when I spotted something unusual in a corner of my office: a shiny, golden Easter egg.

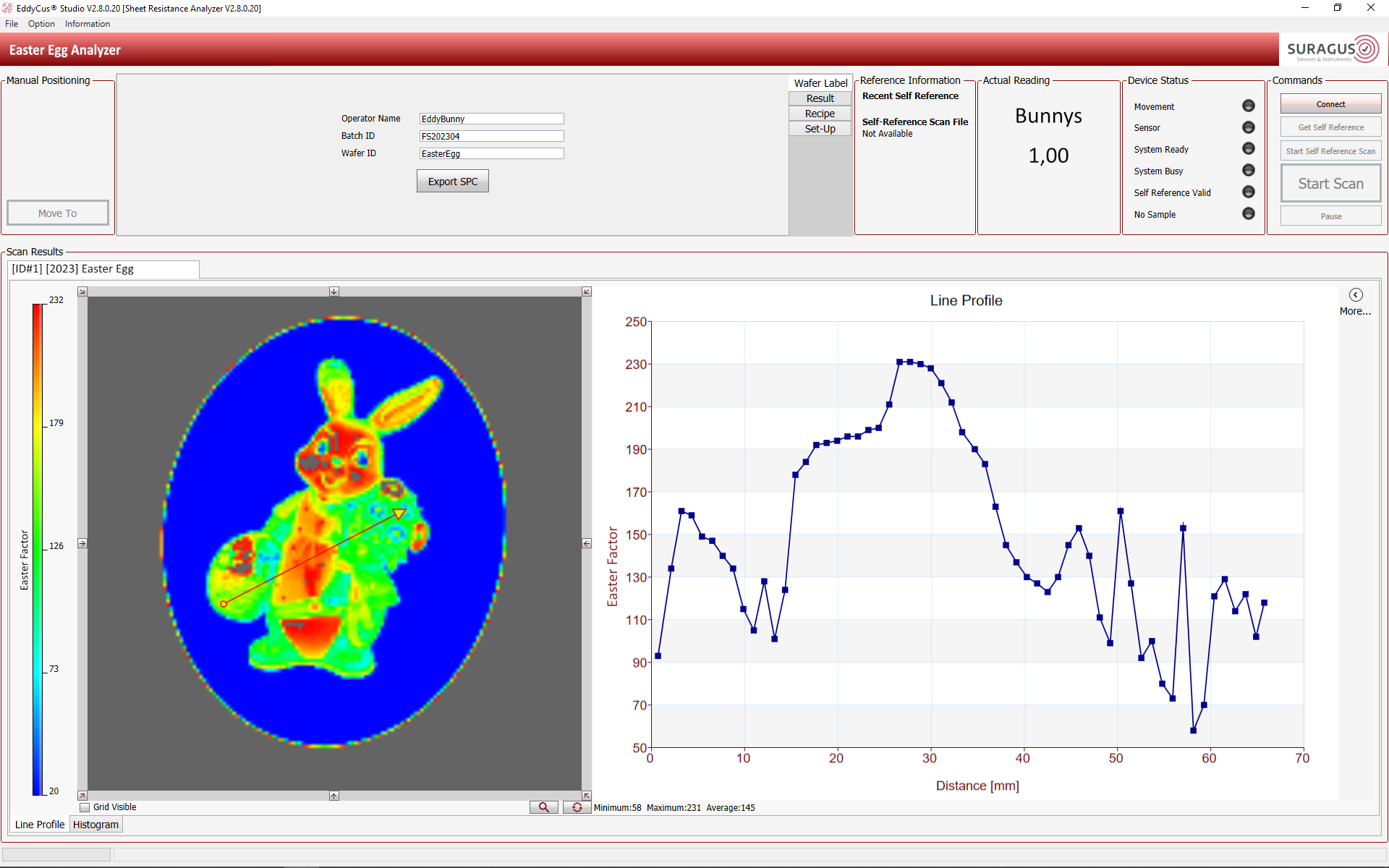

Naturally, I was curious about what might be inside the golden egg, but I was afraid to just crack it open. Maybe it was just a creative Easter decoration, or maybe it belonged to someone else. However, curiosity wouldn't let me go. So I decided to put the egg in our "mapper" and have it analyzed. The device is actually a state-of-the-art scanner for characterizing conductive materials, but I figured it might be useful for my purposes as well. At least that's what they always say "you can measure anything with it."

I snuck into the lab, hoping no one would notice what I was up to. When I entered the room, I carefully placed the golden egg into the measuring device and started the analysis. After a few minutes of waiting, which seemed like an eternity, the process was complete. I couldn't wait to see the results and finally find out what was hiding inside the egg.

The mapping tool's software displayed the results on the screen: To my great surprise, the egg was apparently hollow and housed a small, oval shape - an Easter bunny in an egg! I immediately had to show this to my colleagues. We wanted to open the egg to see if this could be true. But before we opened the egg, we suddenly noticed that something had also changed in the software of the measuring device. On the screen it said in big white letters: "Easter Egg Analyzer".

We couldn't believe what we were seeing. It seemed that because of the golden egg, the software had completely changed and was now able to analyze the secrets of Easter eggs. Our curiosity was piqued, and we placed the egg in the device again to find out what was really inside.

The analysis took a little longer this time, and we waited anxiously for the results. When the process was complete, the mapper showed a detailed picture of the contents of the golden egg. To our great surprise, it was indeed a small chocolate Easter bunny wrapped in a fine shell of edible gold. The software had apparently turned itself into an "Easter Egg Analyzer" and told us the secret of the golden egg.

Happy Easter from the SURAGUS team!