For product requests contact us by using the

- Contact formular,

- Email (sales@suragus.com) or

- Phone (+49 351 32 111 520).

Emissivity Testing by Eddy Current | Characteristics | Correlation of sheet resistance to emissivity | Testing Devices

Emissivity testing by eddy current uses the correlation of the emissivity and sheet resistance which is applied by the architectural glass industry since the late 1980s. Here, the silver coating's ability to transport electrons is used when interacting with incoming visible light. Visible light basically induces an electromagnetic wave, where on atomic scale the electrons are bound to oscillate around a certain orbit, without relevant loss of energy in isolating materials such as glass. Once this electromagnetic wave hits a thin silver layer (e.g. Low Emission), the electrons are able to leave their position and start traveling within the metal film where they quickly lose their energy. Hence, the ability to transport current, correlates with the LowE performance. As sheet resistance measurements using eddy current testing are very easy to apply, this technique is the key technology to characterize emissivity within the glass processing industry. The key benefits of eddy current emissivity testing are:

Optical coatings may require thin films that increase the reflection (R) of significant parts of the infrared (IR) wavelengths, such as Solar Control and Low Emissivity (LowE) applications for architectural glass and its retrofit. These are typically hard (pyrolytic) and soft (PVD or MSVD) coated Ag thin films, in addition to seed and oxide layers. The trend towards de-carbonization requires higher performance from high-solar-gain LowE to low-solar-gain LowE. This can be achieved by single, double and triple silver LowE, applied into dual pane integrated glass unit (IGU) or triple pane IGU on position 2, position 4 or position 6. Finally, LowE coating performance is being described by U value (heat transmission coefficient), the solar heat gain coefficient (SHGC), its visible light transmittance (VLT) and the ratio of light to solar gain.

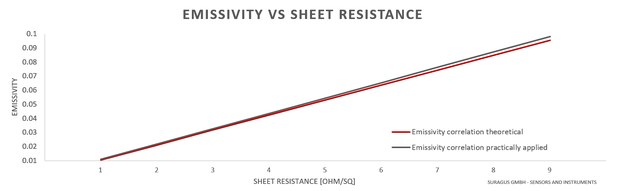

The propagation of electromagnetic waves in matter is described by the MAXWELL equations. The values of transmittance, reflectance and absorptance can be derived from the solutions to these equations. The interaction of the visible light with the layers was very well investigated among industry and science and simplifications for the set of equations have been made and evaluated. MAXWELL equations for the absorptance with consideration of KIRCHHOFF’S Law (emissivity ε = absorptance α) result to εn = αn,IR = 4·R□/zo where R□ is the sheet resistance of the layer and zo = 377 Ω is the wave resistance in vacuum. This results to εn = (4 / 377 Ω) · R□ and is typically written as εn = 0.01061·R□. The industry adds typically some “safety markup” when applying this formula for QA and process control. Often this formula is used e = 0.0108 Rsq. You can calculate the emissivity sheet resistance correlation with our emissivity calculator by choosing emissivity as parameter.

Numerical calculations show that for Ag layers in the thickness range from 5 nm to 20 nm the emissivity Ԑ does not depend explicitly on the film thickness. For further information, please refer to J. Szczerbowski and A. Dietrich, Evaluation and control of the optical and thermal properties of low-emissivity coatings, SPIE Vol 302 (1988).

Industry and R&D laboratories have different requirements when it comes to number of measurement samples per day, measurement point density and automation level. In result, different types of testing setups are commonly applied in architectural glass, automotive glass and transportation glass industry:

Besides typical quality assessment (QA) aspects, high quality glass processing companies require short ramp up times and fast failure and defect detection. The control of the homogeneity of deposition and tempering processes and the reduction of down time facilitates an increase of quality and productivity in architectural glass, automotive glass (e.g. windshields) and transportation glass applications. The solutions address requirements of equipment manufacturers for coatings, equipment manufacturers for tempering process and of the glass processing industry.

For product requests contact us by using the