For product requests contact us by using the

- Contact formular,

- Email (sales@suragus.com) or

- Phone (+49 351 32 111 520).

For narrow production width, slower speed or a general trend control a single traversing sensor can provide enough information along and across the web. The traverse equiped with one or more sensors can detect gaps, capture fiber orientation and measure the fiber areal weight during production process of the fabrics. As a result, the process engineers are enabled to control the key information of recycled carbon fiber material, non-crimp fabrics and UD tapes. Using the inline process monitoring, the quality assurance can use the just measured data to improve the ongoing production process. A roll report shows the ok and not ok areas.

By using the SURAGUS EddyCus® inline GAP traversing sensors, you will be able to detect gaps, capture the fiber orientation and measure the fiber areal weight during the production process. A fixed sensor can not identify gaps accross the whole web. The lateral movement of the EddyCus® inline GAP traversing system eliminates this problem.

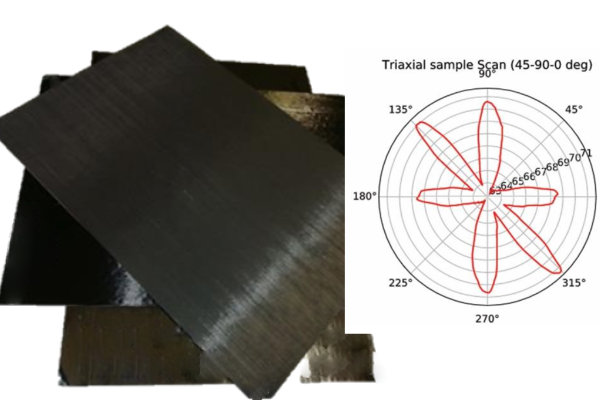

Fiber orientation is one of the most important properties of a carbon fiber component loaded in tension. The fiber orientation directly determines the load limit. This is why the correct angle of the bonded plies is so important.

SURAGUS sensors are adjusted and optimized for the angle to be detected. Each angle to be examined receives its own sensor. The distances between the individual sensors are calculated out to obtain a result that is accurate to the point.

The SURAGUS sensors detect two main measured variables. The angle and the strength of the signal. The strength of the signal allows conclusions to be drawn about the amount of material in the direction under consideration. As shown in the picture, a higher amplitude means a higher surface weight and a lower amplitude means less surface weight. Through our sensors, they will not be able to determine the exact basis weight. Our sensors are calibrated to a target value and relate the measured material to the target value.

How well this works depends very much on the composition. If several layers point in the same direction this is challenging for the analysis. The concept works very well in this case, but due to the missing possibility to separate the layers, only the total weight per unit area can be displayed. This leads to the fact that no recommendations for action can be derived to bring the process to the target values. Contact us to evaluate the applicability in your application.

The software is easy to use and clearly displays the recorded values. A report can be created for each roll and can be handed over to the customer as proof of quality.

To give you an idea of the performance of eddy current technology, we offer you a free demo measurement.

The process goes something like this:

For more information please watch our data sheet or contact us by email.

| Application | Multiaxial Carbon Fiber NCF, UD-Tape (roll-2-roll) |

| Detection capability | Gap >1mm Max undet0ected gap length 5-100mm |

| Value proposition | Roll report, nesting of rolls |

| Production speed | 50-120 m/h |

| Mode | Non-contact |

| Machine interface | I/O, TCP/IP, Modbus |

| Add-ons | Fiber orientation, Tape width, Overlaps |

| Position | Pre-and post stitching or spreading |

For product requests contact us by using the