For product requests contact us by using the

- Contact formular,

- Email (sales@suragus.com) or

- Phone (+49 351 32 111 520).

Equipment manufacturer, producer of manufacturing lines or automation engineering companies may be wondering, if it is possible to integrated the eddy current system into your machinery. The OEM kit is a very lean component and comprises of the basic elements for eddy current testing:

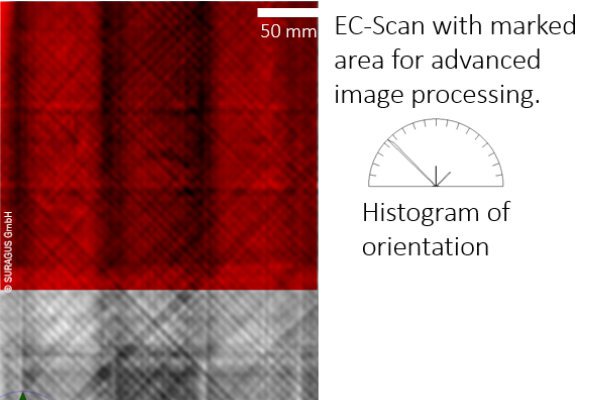

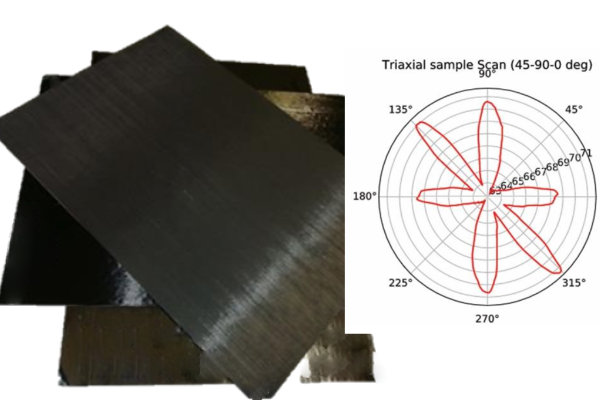

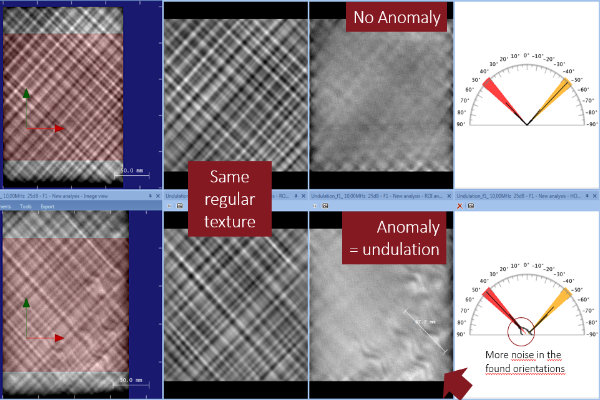

The Eddy Current Sensor Kit is available in different options depending on the measurement task. The most common is the SURAGUS rotation sensor for an automated offline isotropy measurement. The rotation sensor is developed for the analysis of 2D and 3D shaped parts. The sensor is mounted to a robot and takes a line-by-line surface scan and post-analysis with evaluation software (EddyEVA). Our sensors are also compatible with common coordinate measuring machine manufacturers such as Hexagon or Faro. The main application is the display of orientation and fiber area weight of the different layers of a stack. The visualization of the measurement results is done by a polar diagram. The amplitude indicates the fiber area weight or the proximity to the sensor and the angle indicates the fiber orientation. If the position of the plies is known from a reference sample, the fiber area weight can be related and interpreted on the basis of a nominal value.

The EddyCus® rob is a solution for carbon fiber parts with complex geometries. It is capable of scanning 2D to 3D objects and displaying the inner carbon fiber texture and any inherent defects. Regardless of the processing level, e.g. preform or part, the system scans regions of interest and advanced evaluation software helps to classify the information.

The OEM kit is a very lean component and comprises of the basic elements for eddy current testing:

The robot is not part of the system.

Scans perpendicular to the surface and can scan sidewalls at angles up to 60° to provide information on internal texture, such as fiber orientation and gaps. The EddyCus® rob shows hidden defects of up to 10 layers for draped materials such as :

The SURAGUS sensors detect two main measured variables. The angle and the strength of the signal. The strength of the signal allows conclusions to be drawn about the amount of material in the direction under consideration. As shown in the picture, a higher amplitude means a higher surface weight and a lower amplitude means less surface weight. Through our sensors, they will not be able to determine the exact basis weight. Our sensors are calibrated to a target value and relate the measured material to the target value.

How well this works depends very much on the composition. If several layers point in the same direction this is challenging for the analysis. The concept works very well in this case, but due to the missing possibility to separate the layers, only the total weight per unit area can be displayed. This leads to the fact that no recommendations for action can be derived to bring the process to the target values. Contact us to evaluate the applicability in your application.

By separating the different layers, individual defects within a layer can be detected. These include gaps or, as shown in the image on the right, waves.

The software is easy to use and clearly displays the recorded values. A report can be created for each roll and can be handed over to the customer as proof of quality.

To give you an idea of the performance of eddy current technology, we offer you a free demo measurement.

The process goes something like this:

For more information please watch our data sheet or contact us by email.

| Parts geometries | Flat, slightly curved or shaped |

| Scan area | Arm length 1.7 m |

| Accuracy robot | 0.1 mm goal point difference |

| Speed | 500 mm/sec at 0.25 mm resolution |

| Mode | Contact and non-contact |

| Feature | Capturing contour, distance sensor |

| Integration support | CAD files, SDK libraries .net, personal training |

| Software | Evaluation software EddyEVA for 2D and 3D eddy current images |

| Carbon fiber materials | CF fabrics, textile, stack, pregpreg, preform, composite |

| Device dimensions (w/ d/ h), weight | 4.000 mm / 3.000 mm / 2.500 mm, 2.000 kg |

For product requests contact us by using the