For product requests contact us by using the

- Contact formular,

- Email (sales@suragus.com) or

- Phone (+49 351 32 111 520).

The EddyCus® lab 2020 Series allows manual single point measurements of conductive thin films and layer thickness measurement of thin metal layers in non-contact mode. The compact bench-top device is ideal for fast and accurate measurements of samples up to 200 x 200 mm² (8 x 8 inches). In addition to the measurement of thin conductive layers also doped wafers and conductive polymers can be analyzed.

The EddyCus® lab 2020SR is a non-contact single point sheet resistance measurement system. The device contains an eddy current sensor set that induces weak currents into conductive films and material. The induced currents in the specimen generate an electromagnetic field that correlates with the sheet resistance of the measure object. The technology is independent from surface characteristics or morphology. Furthermore, it does not require any sort of sufficient specimen contact or preparation such as known from 2- or 4-point probe testing (2PP, 4PP) or hall effect or Van-der-Pauw measurements. It neither requires the setup of test structures nor it is affected by surface roughness or non-conductive encapsulations or passivation layers. Additionally, the measurement does not physically affect the tested thin-film. Eddy current Instruments have a long-life time since there is mechanical wearing. Its independence from contact qualities and its high speed allows enables high repeatabilities and the accuracies that are beneficial for systematic quality assurance of various thin-films in R&D and testing laboratories. The EddyCus tools can be driven by SURAGUS software with various data recording and export functions or by customer software driven by SURAGUS software development kits.

| Measurement technology | Non-contact eddy current sensor |

| Substrates | Foils, glass, wafer, etc. |

| Substrate area | 8 inch / 204 mm x 204 mm (open on three sides) |

| Max. sample thickness / sensor gap | 3 / 5 / 10 / 25 mm (defined by the thickest sample) |

| Thickness measurement range of metal films (e.g. copper) | 2 nm – 2 mm (in accordance with sheet resistance (cf. our calculator)) |

| Device dimensions (w/h/d) | 11.4” x 5.5” x 17.5” / 290 mm x 140 mm x 445 mm |

| Weight | 10 kg |

| Further available features | Sheet resistance measurement / metal thickness monitor |

| VLSR | LSR | MSR | HSR | VHSR | |

|---|---|---|---|---|---|

| 6 decades are measurable by one sensor, but with slightly affected accuracy | |||||

| Range [Ohm/sq] | 0.0001 – 0.1 | 0.1 – 10 | 0.1 – 100 | 10 – 2000 | 1,000 – 200,000 |

| Accuracy / Bias | ± 1% | ± 1 – 3% | ± 3 – 5% | ||

| Repeatability (2σ) | < 0.3% | < 0.5% | < 0.3% | ||

| VLSR – Very Low Sheet Resistance , LSR – Low Sheet Resistance , MSR – Medium Sheet Resistance , HSR – High Sheet Resistance , VHSR – Very High Sheet Resistance | |||||

You are welcome to contact our team for

The EddyCus® lab 2020MT allows the non-contact metal thicknesses measurement of transparent and non-transparent layers. The measurement is achieved using a non-contact eddy current sensor. It demines the metal thickness of materials with known or (rather) constants conductivity in real-time. This non-contact testing technology enables a precise measurement in a wide thickness range starting at a few nanometer thickness reaching up to the characterization of thick metal sheets and plates. The technology is also able to characterize metal layers that are covered by non-conducive materials. SURAGUS offers material specific setups for very thin layers and also very thick metals and common alloys. The measurement method is extremely robust and excels with a high repeatability and high accuracy. Additionally, it does not require any optical transparency nor to apply a physical contact. Therefore, it is used for a wide range of application for quick tests or systematic quality assurance.

| Measurement technology | Non-contact eddy current sensor |

| Substrates | Foil, glass, wafer, etc. |

| Substrate area | 8 inch / 204 mm x 204 mm (open on three sides) |

| Max. sample thickness/ sensor gap | 3 / 5 / 10 / 25 mm (defined by the thickest sample) |

| Metal thickness range Accuracies depend on the selected setup and the type / conductivity of the metal (e.g. copper, aluminum, silver) |

Low 1 – 10 nm; 2 – 5 % accuracy Standard 10 – 1,000 nm; 1 – 3 % accuracy High 1 – 100 µm; 0.5 – 3 % accuracy |

| Metal thickness calibration | Direct thickness calibration / sheet resistance conversion |

| Device dimensions (w/h/d) | 11.4” x 5.5” x 17.5” / 290 mm x 140 mm x 445 mm |

| Weight | 10 kg |

| Further available features / other tool configurations | Sheet resistance measurement / conductivity / resistivity / electrical anisotropy / permeability (beta) |

You are welcome to contact our team for

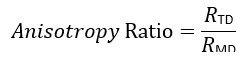

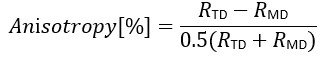

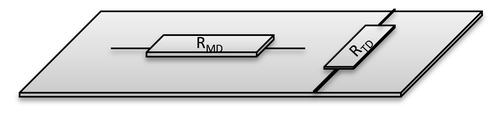

The EddyCus® lab 2020A (Anisotropy) is dedicated to the measurement of the electrical anisotropy and the sheet resistances in certain directions. This is especially relevant for functional thin-film that need to be conductive mainly in a certain direction, while achieving highest optical transparencies. This novel device is equipped with integrated sheet resistance anisotropy sensors. These sensors induce directed currents into machine and traverse direction. The measured directed sheet resistances are used to precisely measure the electrical anisotropy. This non-contact testing method provides results in real-time and prevents time consuming destructive testing. It is used for quick tests and systematic quality assurance in various industries.

| Measurement technology | Non-contact eddy current sensor with directed current induction |

| Substrates | Foils, glass, wafer, etc. |

| Substrate area | 8 inch / 204 mm x 204 mm (open on three sides) |

| Max. sample thickness / sensor gap | 3 / 5 / 10 / 25 mm (defined by the thickest sample) |

| Sheet resistance range | 0.01 – 1,000 Ohm/sq; 1 to 5 % accuracy |

| Anisotropy range (TD/MD) | 0.33 – 3 (larger upon request) |

| Device dimensions (w/h/d) | 11.4“ x 5.5” x 17.5“ / 290 mm x 140 mm x 445 mm |

| Weight | 10 kg |

| Further available features | Metal thickness, sheet resistance, emissivity, resistivity, weight and drying status and also permeability (beta) measurement |

You are welcome to contact our team for

The EddyCus® lab 2020HF is a high frequency eddy current single point measurement device designed for material and thin-film characterization. The device is sensitive to characteristics that correlate with electric, dielectric and magnetic properties. Typical applications include the assessment of material composition, the measurement of residual moisture, wet coating thickness or permittivity, and the determination of the content level of conductive (e.g. C, Pt) or magnetic (e.g. Co) materials. SURAGUS also supports complex impedance analysis to derive information on electrical, dielectric or magnetic properties from hybrid materials with a single measurement. The exact capabilities regarding specific measurement tasks can be provided from a consultation with the SURAGUS team.

| Measurement technology | Non-contact high frequency eddy current sensor |

| Substrates | Foils, glass, various containers |

| Substrate area | 8 inch / 204 mm x 204 mm (open on three sides) |

| Max. sample thickness/ sensor gap | Transmission setup: 3 – 50 mm (defined by the thickest sample) Reflection setups: infinite (only surface area is analyzed) |

|

Measurement types |

Wet thickness (µm) / weight (g/m²) / drying status (%) Conductivity / resistivity (mOhm cm) / permeability (H/m) Beta Permittivity (F/m) Beta |

| Measurement range / accuracy | Depends on the measurement task, the material composition and the test object volume. Please consult the SURAGUS team |

| Device dimensions (w/h/d) | 11.4“ x 5.5” x 17.5“ / 290 mm x 140 mm x 445 mm |

| Weight | 10 kg |

| Further available measurements | Sheet resistance, metal thickness, anisotropy |

You are welcome to contact our team for

The EddyCus® lab 2020RM is a unique industrial eddy current measurement device utilizing frequencies from 10 kHz up to 100 MHz dedicated to the characterization of flat specimen. The variation of the measurement frequency allows the control of the penetration depth. The measurement with high frequencies benefits the characterization of near surface material characteristics of bulk materials and thin films. Additionally, the sensitivity increases with increasing measurement frequency. Therefore, also very low conductive materials and layers can be characterized. Furthermore, the device supports the generation of depth profiles by utilization of multi frequency measurements. Measurement parameters are conductivity and related characteristics.

For product requests contact us by using the