For product requests contact us by using the

- Contact formular,

- Email (sales@suragus.com) or

- Phone (+49 351 32 111 520).

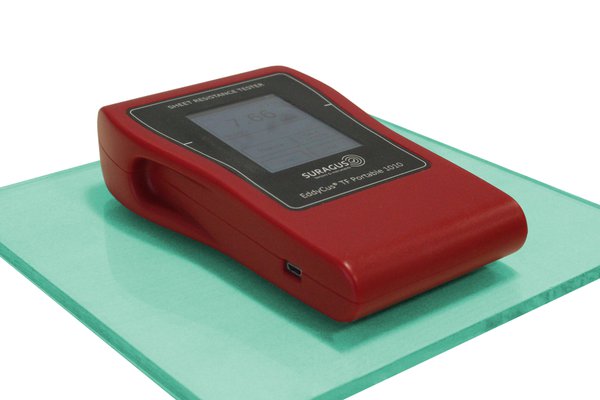

The EddyCus® portable is a handy and portable measuring instrument for fast contact measurement of large glasses and foils in production or in the field, e.g. for fast quality checks after production or as incoming goods inspection. The handheld device also allows the measurement of concealed and encapsulated layers. It is an easy to use device, which is controlled by a touch display.

The EddyCus® lab 2020 enables manual single point measurements of conductive thin films and film thickness measurements of thin metal films in non-contact mode. The compact benchtop instrument is ideal for fast and accurate measurements of samples up to 200 x 200 mm² (8 x 8 inches). In addition to the measurement of thin conductive layers, doped wafers and conductive polymers can also be analyzed.

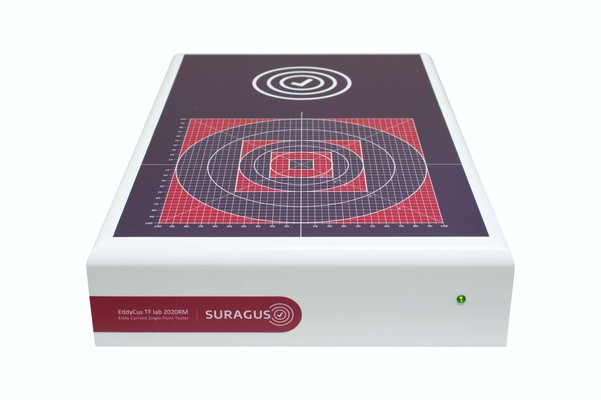

The EddyCus® lab 2020RM is a unique industrial eddy current measurement device utilizing frequencies from 10 kHz up to 100 MHz dedicated to the characterization of flat specimen. The variation of the measurement frequency allows the control of the penetration depth. The measurement with high frequencies benefits the characterization of near surface material characteristics of bulk materials and thin films. Additionally, the sensitivity increases with increasing measurement frequency. Therefore also very low conductive materials and layers can be characterized. Furthermore, the device supports the generation of depth profiles by utilization of multi frequency measurements. Measurement parameters are conductivity and related characteristics.

The EddyCus® map 2530 RMB is designed for non-contact resistivity measurement of bulk and ingots with a height up to 100 mm. Upon manual sample positioning the device automatically measures the sample from the bottom. The software offers predefined recipes with a focus on high resolution, high speed or a compromise between high resolution and high speed.

The EddyCus® map 2530 TM Series automatically measures the sheet resistance of large samples up to 300 x 300 mm² (12 x 12 inches) in non-contact mode. Upon manual sample positioning the device automatically measures and displays an accurate mapping of the sheet resistance across the entire sample area. The measurement settings allow easily and flexibly to choose between fast measurement times of below 1 minute or high spatial measurement resolution of more than 100,000 measurement points.

The EddyCus® ResMapper is a fully automated wafer mapping system with automated contactless wafer handling. The device combines a high throughput of 45 wafers per hour with a bunch of high resolution and high quality measurements. The device records maps of sheet resistance, metal layer thickness, and resistivity using eddy current sensors. Further measurement options are the total thickness variation (TTV), bow and warpage using opical sensor.

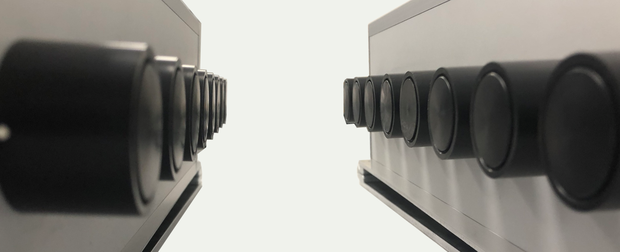

The EddyCus® inline series measures layer properties such as metal layer thickness or sheet resistance in non-contact on various substrates. Typical substrates are glass, foil, paper, wafer, plastic or ceramic. Measurements are obtained by permanent measurements or by trigger events to obtain equidistant results in fast moving coating processes or measure on specific positions on small specimen. Monitoring is possible in atmosphere and in vacuum. The measurements are obtained using high samples rate and can be directly provided for process control systems and customer software. Additionally SURAGUS offers the monitoring software EddyCus TF control that visualizes, stores and analyses metrology data.

Eddy Current full-area monitoring is achieved by by use of EddyCus TF array solution. SURAGUS provide stackable 8 Sensor Modules which allow depending on its configuration the inline monitoring on upto 128 measurement lanes

EddyCus full-area inline solutions help to monitor the entire width of small and large area coatings. This enables to track the complete product and process quality optimally. Since you can only improve things that you can measure, our solution enables you to optimize your product and process quality. This gives you a big advantage over your competitors. With our software it is easy to analyze your data perfectly. It is really simple to monitor the process and product data and let you improve your output while monitoring your product quality and process data.

The EddyCus® inline WT series are designed for the non-contact continuous inline testing of any conductive wire sharped materials. This solution enables process control, increase of yield, and incoming and outgoing goods inspection.

| Sheet resistance (SR) | Metal thickness (MT) | Conductivity / structure / defects (CT) | Optical transparency/ density (OT) | Electrical (an)isotropy (AI) | |

| Handheld | EddyCus® portable 1010SR | EddyCus® portable 1010MT | EddyCus® portable 1010RM | ||

| Single point | EddyCus® lab 2020SR EddyCus® lab 4040SR | EddyCus® lab 2020MT EddyCus® lab 4040MT | EddyCus® lab 2020RM EddyCus® lab 2020HF EddyCus® lab 4040RM EddyCus® lab 4040HF | EddyCus® lab 4040A EddyCus® lab 2020A | |

| Imaging | EddyCus® map 2530SR EddyCus® map 2530SR | EddyCus® map 2530MT EddyCus® map 2530MT | EddyCus® map 2530RM EddyCus® map 2530RM EddyCus® map 2530HF EddyCus® inline HF | EddyCus® map 2530A EddyCus® map 2530A | |

| Inline | EddyCus® inline Sensorline EddyCus® inline SR EddyCus® inline SR | EddyCus® inline MT | EddyCus® inline RM | EddyCus® inline A |

For product requests contact us by using the