Elektrische Anisotropy Measurement

内容概述

目录

涡流法测量电学各向异性

The measurement of electrical anisotropy by eddy current anisotropy sensors allows the precise measurement the anisotropy strength and anisotropy direction without sample preparation or even contacting the test object. The key of this innovation is the induction of directed eddy currents into thin films and the subsequent determination of directed sheet resistances by electromagnet field (EMF) sensors. Anisotropy sensors and instruments save a tremendous amount of time since a measurement can be done in milli-seconds. Further benefits include

- No sample preparation

- Non-contact & non-destructive

- 通过封装进行测量

- Determination of anisotropy strength

- Determination of anisotropy direction

- 高重复性和准确性

- Large anisotropy measurement range 0.25 to 4 (MD / TD, larger on request)

This technology is applied in industrial applications since 2015. The dedicated EddyCus SR-A series includes single point, imaging and inline devices. Those systems determine the directed sheet resistance in two or four directions and present the data as numbers, graphical bars or as anisotropy images.

Terminology – What is Electrical Anisotropy?

定义

The available definitions of electrical anisotropy are often addressing the background of its application. The general definition of electrical anisotropy describes the variation of an electrical property depending on the lateral or vertical direction (x,y,z) in which is a current flows. In other words, the term “electrical anisotropy” describes the directional dependence of the electrical conductivity or resistivity or other electrical terms such as sheet resistance or carrier mobility. The scale of anisotropy can be microscopic or macroscopic and even be different on small and large scale.

Concept and Terminology of Sheet Resistance Anisotropy

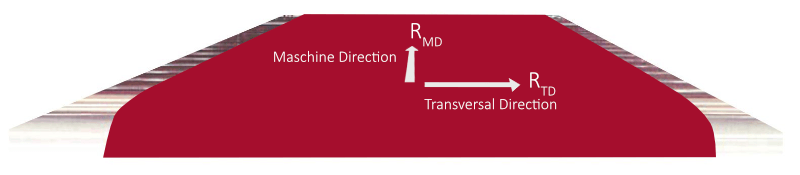

MD = Machine Direction TD = Transversal Direction

RMD = Sheet Resistance in MD RTD = Sheet Resistance in TD

The anisotropy depends on the material, the process type and process parameters. There are isotropic or rather isotropic processes such as PVD or CVD processes. There are also high throughput processes such as slot die coating or curtain coating which generate anisotropy depending on process parameters such as speed or if measures are taken to reduce or increase anisotropy. Furthermore, there are also high anisotropic applications e.g. screen printing in PV industry where the metal meshes structures (fingers) are designed for efficient current transport towards the collectors. An overview in typical anisotropy rations is given here.

| 进程 | Calculation |

| Isotropic processes | RMD = RTD |

| Anisotropic processes |

RMD < RTD RTD / RMD = 1.0 – 1.2 or 1.2 – 2.0 |

| Forced anisotropic processes (e.g. by mesh design) |

RMD << RTD RTD / RMD = 2 – 200 (and higher) |

Calculation of Sheet Resistance Anisotropy

The relevant directions for anisotropy calculation are the minimum (Rdirection min) and the maximum (Rdirection max) sheet resistance direction. Most inline manufacturing processes tend to align the wires into machine direction when transferring wire or tube material onto moving web. Therefore, the best or minimum sheet resistance is present in machine direction. Consequently, the worst or highest sheet resistance is achieved into the traversing direction.

Rdirection max = RTD Rdirection min = RMD

Generally, the best sheet resistance direction Rdirection min is perpendicular to worst sheet resistance Rdirection max.

Rdirection max = Rdirection min + 90 degree Rdirection min = Rdirection max + 90 degree

There are two common ways to describe anisotropy. Either the ration between the lowest and highest sheet resistance is taken. An alternative way is the description of the difference of both directions divided by the average.

Relative Anisotropy = RTD / RMD Anisotropy [%] = (RTD – RMD) / ((RMD + RTD) · 0,5)

Electrical Anisotropy in Transparent Conductive Materials.

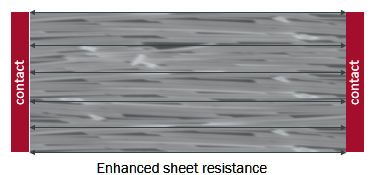

Transparent conductive materials excel in electrical conductivity and in optical transparency at the same time. The challenge for TCM manufactures is that the electrical resistance can be improved by adding more material which is then worsening the transparency. Many companies compete for providing the best sheet resistance to transparency ratio. Nanowire, tube and mesh structure are able to provide outstanding SR to OT rations at good costs. There are some cases where the conductivity of a film is directed to the electrodes which results in even better SR to OT rations. The key points of this concept are shown here:

Anisotropic Wire Film

- Anisotropy can be optimized according to the layout of the contact pattern

- Anisotropy can save material and improve optical transparency

- Anisotropy can be measured in non-contact mode by EddyCus TF inline anisotropy sensor

Isotropic Wire Film

- More of the conductive (and non-transparent) material is required in order to sufficiently supply this structure with current

Types of Tools for the Measurement of the Electrical Anisotropy

台式工具

用于单点测量

我们的手持式系统非常适合快速抽样检测——无论是货物入库时、生产过程中的检验,还是对于大型部件进行检测时,当固定设备难以操作时。

只需将手持设备放置在待测表面,按下“测量”按钮,一秒钟内测量值即会显示在屏幕上。

每次读数都代表测量点处的精确数值——在您需要的地方为您提供快速、可靠的反馈。

成像工具

全区域图像

我们的技术可提供高度详细、覆盖全表面的产品质量信息,从而对工艺质量和稳定性得出有意义的结论。这些数据支持对制造工艺(例如资源效率、吞吐速度)和产品本身(例如提高均匀性、符合最低规格要求)进行有针对性的优化。

测量时,将样品置于测量区域的中心位置。预制样品托架(如晶圆托架)可确保精确居中定位。只需放入样品,关闭托架盖板,按下“开始测量”按钮即可。

结果:通过数千个独立测量点生成的整个层的高分辨率伪彩色图。这种可视化效果让您一目了然地获得可操作的洞察。

内联系统

用于连续单点测量

我们的在线系统能够在生产步骤之前、期间或之后,持续采集工艺质量和产品特性的数据。这种实时监测是生产自动化的基础,其运作依赖于精准可靠的传感器数据。

该系统可无缝集成至您现有的生产线。操作员启动测量后,所有数据将自动记录并存储于集中式数据库中。

根据系统配置,输出结果包含一条或多条线性剖面图——这些剖面图可居中显示,或定位于层面的关键点——从而实时清晰呈现质量趋势与工艺稳定性。

Measurement of Electrical Anisotropy

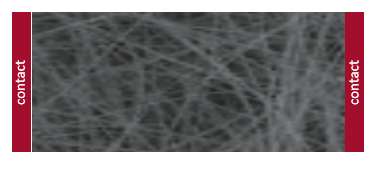

The measurement of the resistivity anisotropy may expose insights about the material structure and scattering processes in anisotropic and low-dimensional materials. Its anisotropy is affected by the geometry of conductors, its connection, the number contact points and length paths and the effective parallel resistances.

A difference in lateral (y,x) sheet resistance / resistivity / conductivity within a material or film can be measured by contact or non contact testing methods. Contact methods require the cut out of narrow and long material sections in a ration of 1 : 20 (eg. 1 cm x 20 cm). Here the direction of the cutout describes the direction measurement. The sheet resistance can be measured by contact measurement after applying contact pad to the material film. The nature of this setup results in the disadvantage that a measurement on the same position is not possible. The layout of possible cut outs is shown at the right.

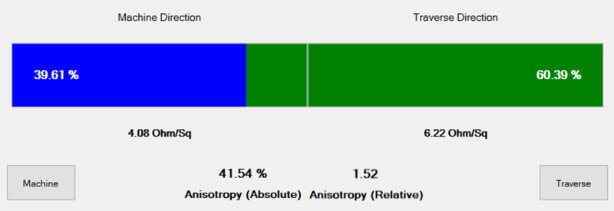

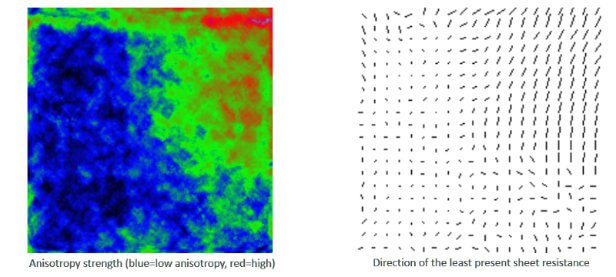

Non-contact measurement of electrical anisotropy is done by SURAGUS Eddy Current anisotropy sensors. Those are especially designed to induce currents in defined directions such as MD = Machine Direction | TD – Transversal Direction. There are single point measurement systems and imaging measurement systems proving in detail information on anisotropy strength and direction across the entire sample. Examples for sheet resistance anisotropy depiction are shown below. The first images shows the individual sheet resistances RMD and RTD and the absolute and relative calculated values. The right image depicts the anisotropy distribution across a sample where blue represents anisotropic areas and red anisotropic areas. The black and white line image depicts the anisotropy strength as length of the lines where dots represent isotropic areas and long lines anisotropic areas. The direction of anisotropy is exposed by the direction of a line.

Single point / inline

Single Point Anisotropy Evaluation with Eddy TF lab 2020A Series

成像

Anisotropy Image of Spray Coated Silver Nanowires.

Testing Devices for Anisotropy Measurements

工业与研发实验室根据每日测量样本数量、测量点密度及自动化程度存在不同需求。因此,通常应用四种关键测试类型:

- 手持式

- 实验室 / 台式

- 单点

- 成像

- 内嵌式 / 工具集成式

- 内嵌式静态单/多传感器