Eddy Current Sensors for

Conductive Thin-films and Materials

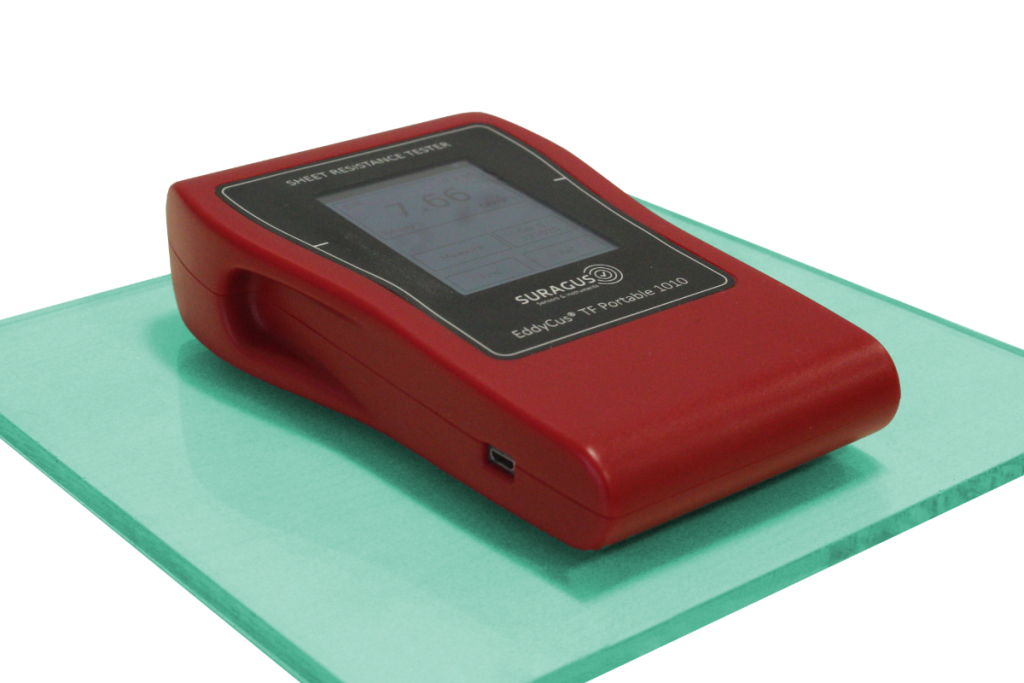

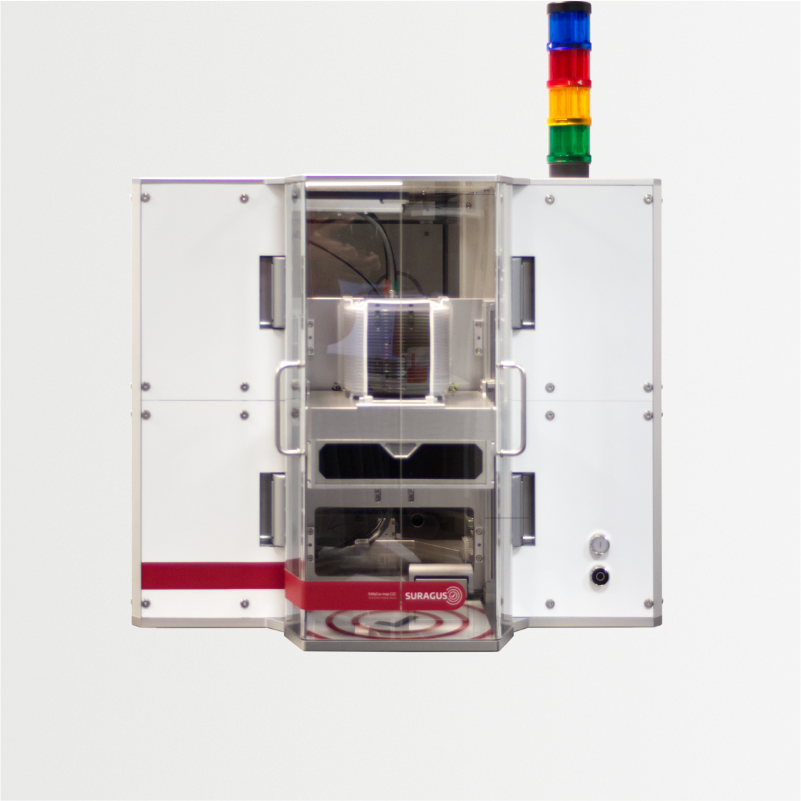

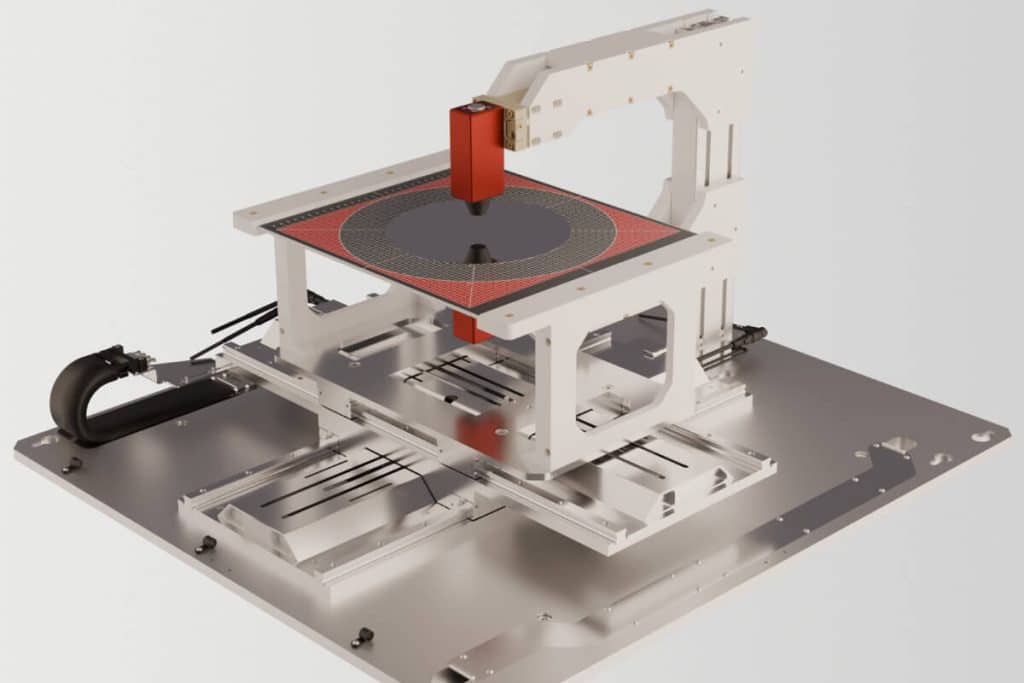

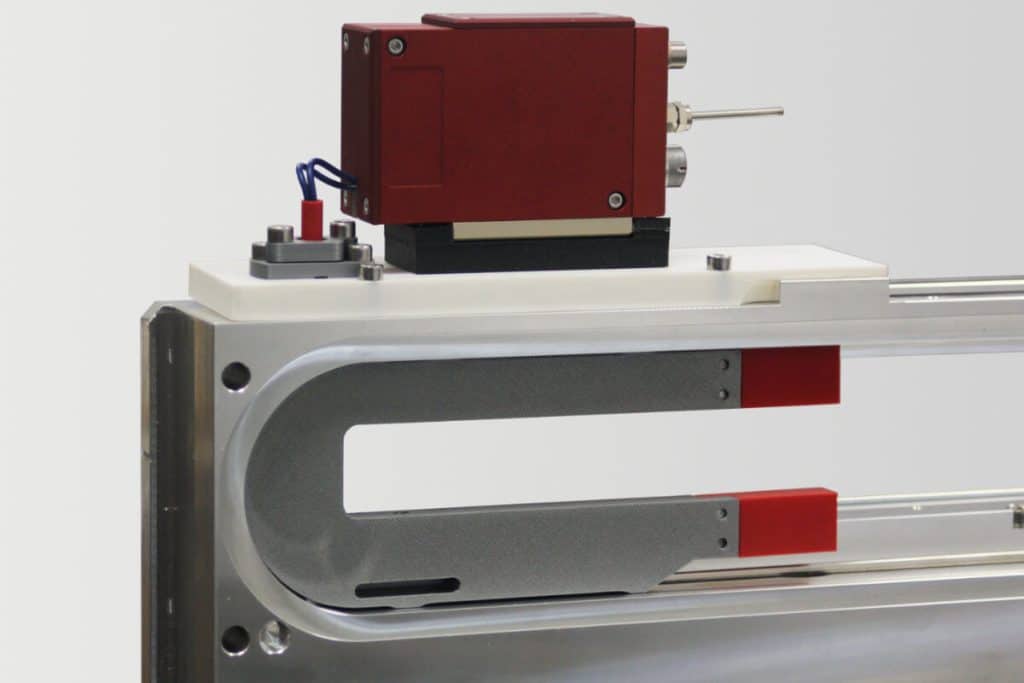

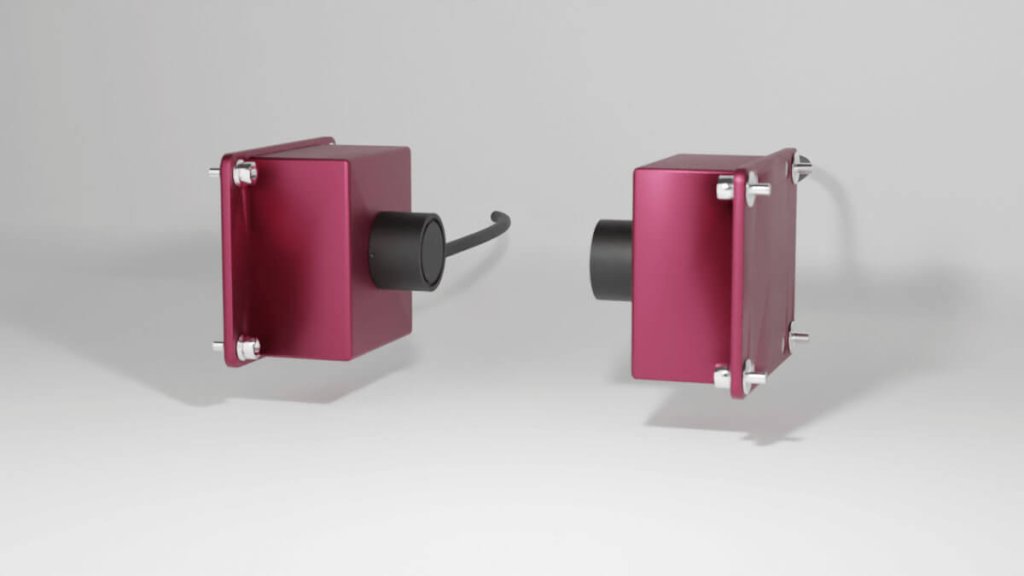

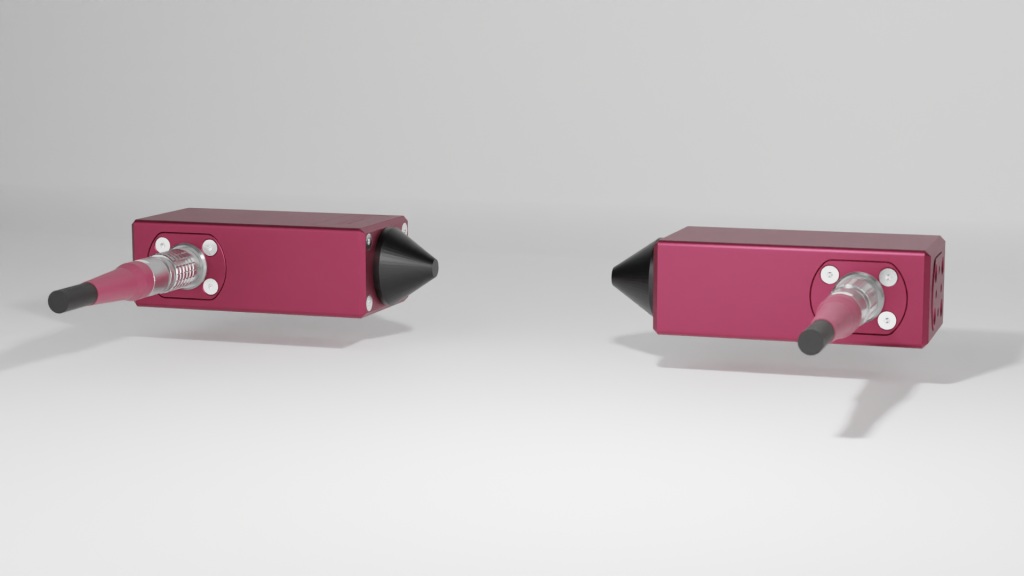

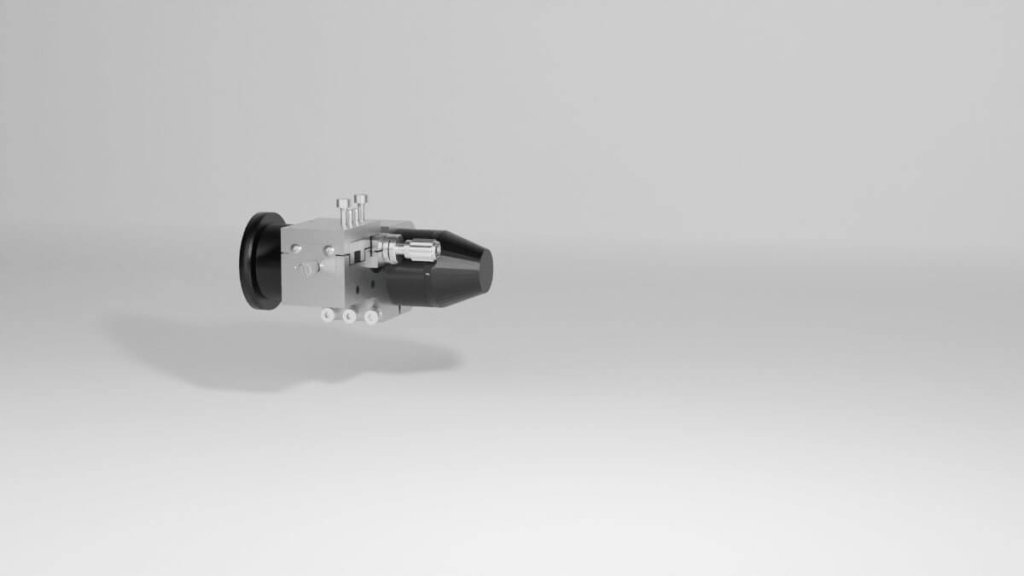

We design and manufacture a complete range of measurement solutions—from ergonomic handheld instruments and versatile laboratory systems for single‑point and mapping analysis to robust inline platforms that deliver real‑time quality assurance and process control.

- High Speed

- Non-Contact

- Flexible Inline Integrations

- Mass-production Proven Inline Technology

- Your Expert with Worldwide 24/7 Customer Support

We Work With:

Calculation Tools

Go directly to the sheet resistance calculator or penetration depth calculator, and explore our extensive parameter library.

Contact Sales Team

Finding the right measurement solution can be challenging. We help you choose the perfect fit – tailored to your process and goals.

Finding the right measurement solution can be challenging. We help you choose the perfect fit – tailored to your process and goals.

Contact Human Resources

Are you looking for a new job opportunity?

Do you have a question about our job offerings or a question about your application?

Meet With SURAGUS

Find Us at These Events

We’re on the road year-round—sometimes as exhibitors, sometimes simply walking the floor at leading conferences and trade shows. Want to meet up? Send us an email and we’ll gladly schedule a time, either during the event or over a coffee nearby.

Conductivity Measurement by Eddy Current Sensors

Eddy current gauges and sensors are commonly applied for conductivity and resistivity measurement across many industries. Most systems operate in contact but there are also non-contact options available. The eddy current method is used for various reasons of which some are listed below:

Quick Facts About SURAGUS

2010 Founded in Dresden

Founded in 2010 in Dresden, SURAGUS has grown into a team of more than 50 experts—engineers, physicists, and technicians—driven by a shared passion for precision and innovation.

From our R&D and manufacturing facilities in one of Germany’s leading high-tech hubs, we push the boundaries of what’s possible in non-destructive testing. Our creative engineering spirit and deep technical know-how power the development of cutting-edge eddy current solutions trusted by industry leaders worldwide.

100 Eyes of Argus

Our name is inspired by mythology and technology: Argus Panoptes, the all-seeing giant with 100 eyes, symbolizes constant vigilance. We apply that same principle to the surfaces and thin films you rely on.

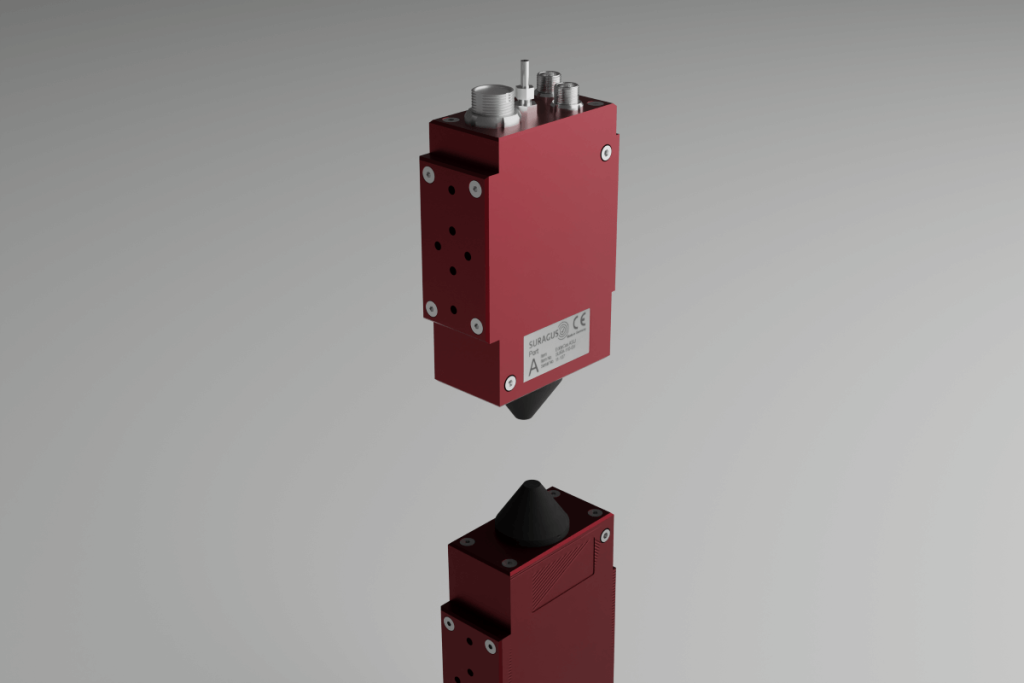

SURAGUS stands for SURface ArGUS—your Surface Guard. Our high-frequency eddy current sensors act like 100 eyes on your process, delivering precise, non-contact measurements exactly where they matter most.

2,000+ Sensor Units

Our high-frequency eddy current sensors are installed in over 2,000 production lines and measurement labs across the globe. From OEMs to industry and innovation leaders, we support customers in the US, Asia, Europe—and every other major region worldwide.

Our systems are running reliably on six continents, delivering the precision and consistency process engineers depend on.

1 Testing Technology

At SURAGUS, we specialize in one thing—and we do it exceptionally well: high-frequency eddy current sensors for material and thin-film characterization.

By dedicating ourselves to a single technology, we aim to become the world’s leading authority in eddy current measurement. This laser-sharp focus allows us to push boundaries, refine performance, and deliver unmatched precision for process engineers who demand reliable, real-time data.

Carbon Fiber Testing

The EddyCus® series specially addresses the carbon fiber processing industry. The non-destructive testing portfolio comprise solutions for roving or tow manufacturing, for fiber spreading, weaving and layup, draping/ preforming, injection and infusion (RTM) as well as pultruding processes, composite testing and recycling processes. This involves gap detection, orientation assessment, fiber areal weight (FAW) determination, isotropy testing as well as the detection of further effects and defects in carbon structure and matrix.

Inline R2R / S2S Sensor System

The EddyCus® series specially addresses the carbon fiber processing industry. The non-destructive testing portfolio comprise solutions for roving or tow manufacturing, for fiber spreading, weaving and layup, draping/ preforming, injection and infusion (RTM) as well as pultruding processes, composite testing and recycling processes. This involves gap detection, orientation assessment, fiber areal weight (FAW) determination, isotropy testing as well as the detection of further effects and defects in carbon structure and matrix.

Inline Wafer Monitoring System

Different high efficiency wafer-based cells are available. Cell and module manufacturing is cost driven. For achieving highest efficiency at lowest manufacturing cost, the following processes have to be monitored:

- Incoming wafer

- Metal grid

- Electrodes

- Buffer or seed layer

- Tunnel oxide

- Passivation layer