Full-area Sheet Resistance and Layer Thickness Measurement Solution for Process Control

Higher Thin-film and substrate quality through fast and precise multi sensor Inline Measurement based on non-contact eddy current technology.

- Non-contact real time measurement

- High measurement speed up to 50 measurements/ sec.

- Fixed sensor installation or traversing sensor installation

- Integration of 1 – 99 monitoring lanes per system

- Process control at atmosphere or in vacuum

- Measurements very close to the edge of the substrate are possible in many applications

- Long term stability by temperature compensated measurements in changing environment

- Large distances to the testing material (e.g. gap of 60 mm / 2.4 inch)

- Characterization of covered conductive layers or encapsulated substrates

- Numerous software integrated analysis and statistic functions

- Easy set up by EddyCus RampUp software incl. wizard for system calibration

- Wear-free

Introduction

Eddy Current full-area monitoring is achieved by use of EddyCus® inline Sensorline solution. SURAGUS provide stackable 8 Sensor Modules which allow depending on its configuration the inline monitoring on up to 128 measurement lanes.

EddyCus full-area inline solutions help to monitor the entire width of small and large area coatings. This enables to track the complete product and process quality optimally. Since you can only improve things that you can measure, our solution enables you to optimize your product and process quality. This gives you a big advantage over your competitors. With our software it is easy to analyze your data perfectly. It is really simple to monitor the process and product data and let you improve your output while monitoring your product quality and process data.

The EddyCus® inline series measures layer properties such as metal layer thickness or sheet resistance in non-contact on various substrates. Typical substrates are glass, foil, paper, wafer, plastic or ceramic. Measurements are obtained by permanent measurements or by trigger events to obtain equidistant results in fast moving coating processes or measure on specific positions on small specimen. Monitoring is possible in atmosphere and in vacuum. The measurements are obtained using high samples rate and can be directly provided for process control systems and customer software. Additionally, SURAGUS offers the monitoring software EddyCus inline control that visualizes, stores and analyses metrology data.

Sensor Capabilities

- Sheet Resistance [0.0001 – 100,000 Ohm/sq]

- Metal Layer Thickness [2 nm – 2 mm]

- Gap up to 75 mm

- Scanning pitch 40 mm

- Up to 128 sensors

Supported Substrates

Foils, glass, wafer, paper, etc.

Software

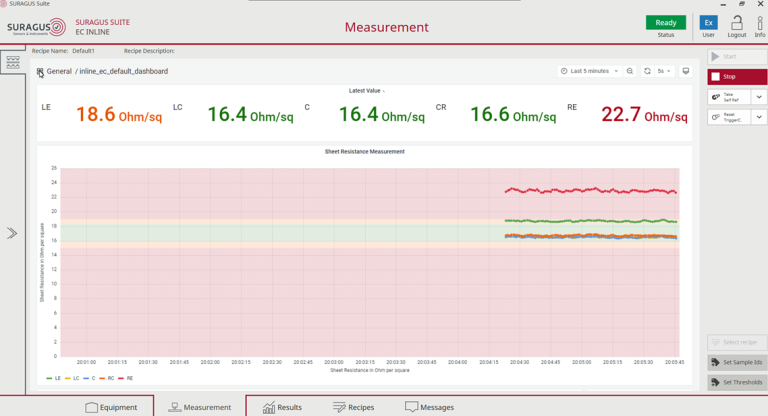

- Several views and user level

- Live view with upper and lower limits and alarm functions

- Analysis view providing statistics

- Can handle data of several thousands measurements per second

- Data storage into SQL database

- Customizable automated data export (csv, txt, xls,…)

- Several smart functions (automated DB cleaning, self-reference etc.)

- Parameterizable I/O modules (triggering of actions or alarms)

Data Table for EddyCus® inline Sensorline

System Features

| Measurement technology | Non-contact eddy current sensor |

| Substrates | Foils, glass, wafer, paper, etc. |

| Measurement gap size | 3 / 5 / 10 / 15 / 25 / 50 / 75 mm |

| Number of monitoring lanes | Up to 128 sensors |

| Conductive layers | Metals / TCOs / CNTs / nanowires / graphene / grids / PEDOT / others |

| Scanning pitch | 40 mm (5 mm – 100 mm upon request) |

| Environment | Ex-vacuo/ in-vacuo @ T < 60°C / 140°F (on request <90°C / 194°F) |

| Sample rate | 1 / 10 / 50 per second |

| Hardware trigger | 5 / 12 / 24 V |

| Interfaces | UDP, .Net libraries, TCP, Modbus, analog/digital |

| Available options | 8-sensor array, 40 mm pitch (total array width of 320 mm)* 16-sensor array, 40 mm pitch (total array width of 640 mm)* 32-sensor array, 40 mm pitch (total array width of 1,280 mm)* 48-sensor array, 40 mm pitch, (total array width of 1,920 mm)* 64-sensor array, 40 mm pitch (total array width of 2,560 mm)* * with standard sensor housing |

Measurement Capabilities

| Sheet resistance measurement | |

|---|---|

Sheet resistance range Accuracy can be optimized over sheet resistance decade |

0.0001 – 100,000 Ohm/sq; 2 to 7 % accuracy | Metal layer thickness measurement |

| Thickness measurement range of metal films (e.g. copper) | 2 nm – 2 mm (in accordance with sheet resistance (cf. our calculator)) |

Frequently Asked Questions

Sheet resistance, metal layer thickness, resistivity

Up to 128 sensors