Higher Quality of Your Fabrics and CFRPs

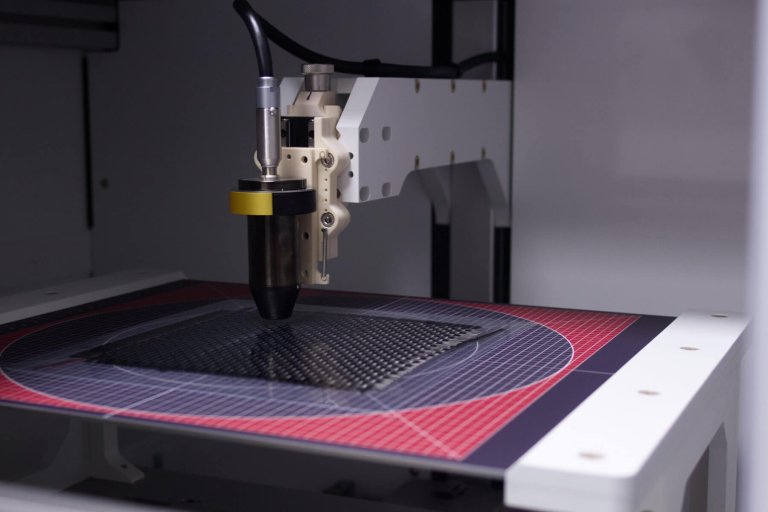

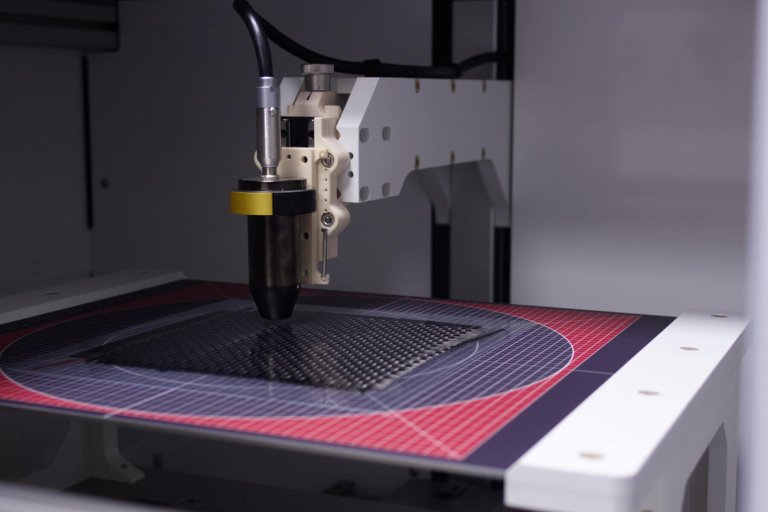

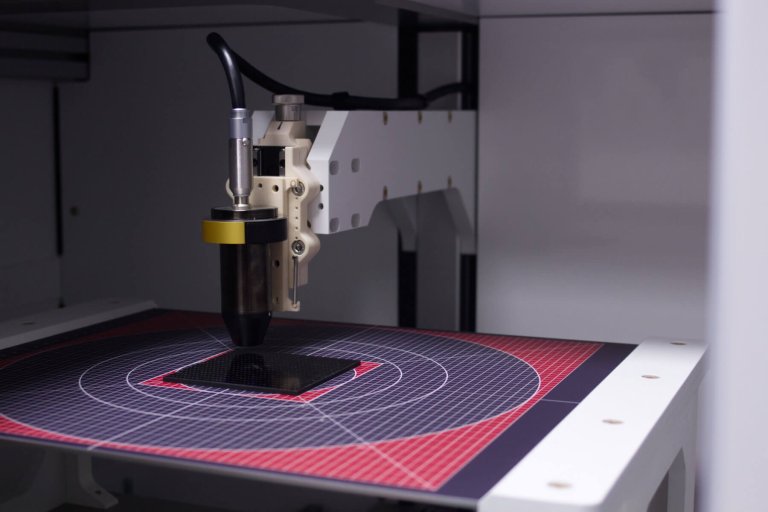

The EddyCus® map 2530 RMT is a high quality, fast and precise benchtop mapping device based on non-contact eddy current technology. The tool makes high resolution images of your fabrics and CFRPs and helps you to find defects and examine the structure.

- Display of inner structure such as fiber orientation and gap distribution

- Reveals potential defects inside the stack

- R&D or at-line testing of automotive or aircraft parts

Introduction

The EddyCus® map 2530 RMT is a bench top scanner particularly suitable for research and technology labs. It is fully functional to measure carbon fiber parts, plates or textiles for inner defects and texture. It’s a compact device, which provides up to 300x300mm²; area for samples to be tested non-destructively.

The device is typically used for:

- Quality control of fabrics and CFRPs

More Information

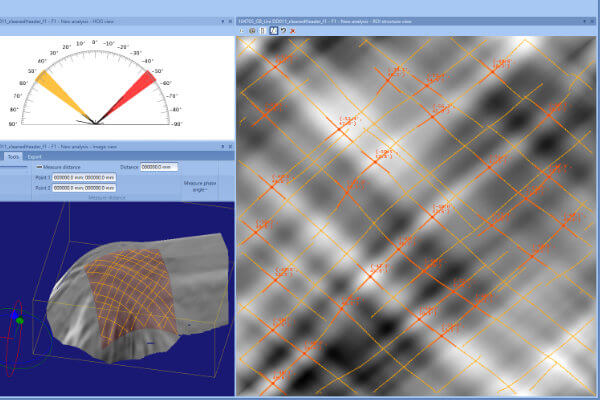

Most Accurate Analysis on the Market

Due to the best imagings on the market, the analysing capabilities are endless. Especially since the carbon fabric is not only viewed from the outside, but the inner layers can also be examined. The EddyCus® map 2530 RMT uses two non-contact high-frequency eddy current sensors that are capable of penetrating up to 10 layers of carbon fabric to generate a mapping of inner layer to determine uniformity of fiber orientation and gaps and to reveal defects such as:

- Wrinkles

- Folds

- Distortion

- Gaps

- Wrong stacking

- Undulation

- Misalignment

- Fuzz balls

- Overlaps

One Tool For a Wide Range of Applications

The EddyCus® map 2530 RMT can handle many different materials such as:

- Non-woven

- Non-crimp

- Woven

- UD-Prepreg

- Other

Due to the high accuracy and repeatability it is valuable for industries applications such as:

- Specimen from automotive carbon fiber parts

- Cut-outs from textiles and fabrics

- Partial aircraft structures

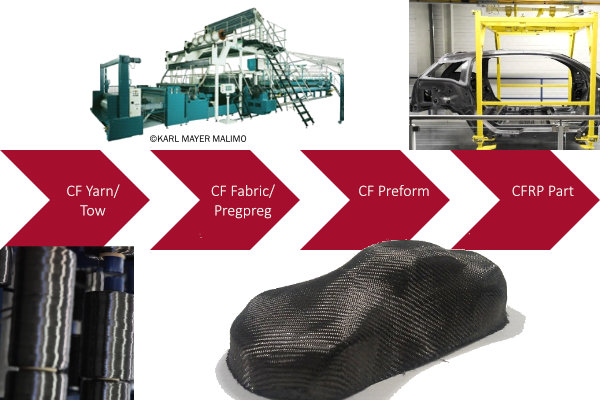

One Supplier For Almost All Process Steps

The EddyCus® map 2530 RMT is suitable for 2D materials such as fabrics and pregpregs. SURAGUS offers also tools to characterize products in other process steps.

- CF yarn and tows

- CF preforms

- CFRP parts

Benefit from a single point of contact for monitoring all your process steps.

Demo Measurement To Show Feasibility

To give you an idea of the performance of eddy current technology, we offer you a free demo measurement.

The process goes something like this:

- You contact our sales team and describe your application case

- We evaluate whether the eddy current technology is suitable for your application

- For highly innovative materials a non-disclosure agreement can be made in advance

- You send us your samples

- We measure your samples

- We contact you and discuss the measurement results together

Data Table for EddyCus® map 2530 RMT

| Parts geometry | Flat and curved |

| Mode | Contact and non-contact |

| Scan area | 300 mm x 300 mm x 40 mm |

| Sensor mobility | X and Y direction |

| Min. pitch | 0.1 mm |

| Speed | 160 mm per second (full scan: 30 min) |

| Carbon fiber materials | CF fabric, textile, stack, prepreg, preform, composite |

| Device size (w/h/d) / weight | 31.5“ x 19.1“ x 33.5“ / 785 x 486 x 850 mm / 90 kg |