Retro-fit Sensor Integration

for

Deposition Cluster Tools

Sheet Resistance · Metal Layer Thickness · Resistivity

- Non-contact real time measurement

- High measurement speed up to 1,000 measurements/ sec.

- Fixed sensor installation or traversing sensor installation

- Line profile before and after deposition

- Process control

Introduction

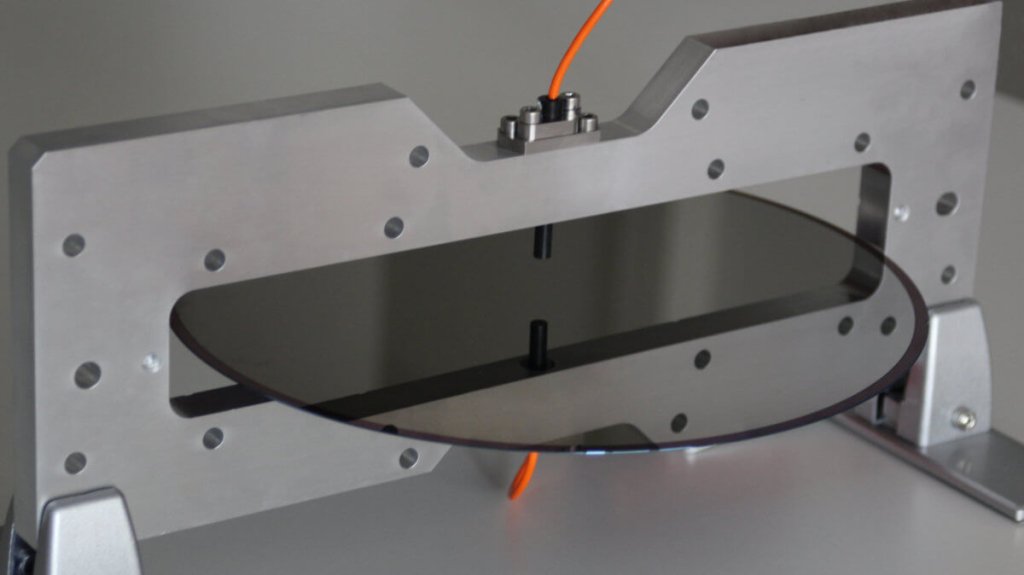

The EddyCus® inline ICM (interconnection module) is a measuring module that is installed between a coating chamber and the central wafer handling chamber. It consists of two non-contact eddy current Sensor XXS operating in transmission mode and a connection module.

It is dedicated to measure the sheet resistance [Ohm/sq] or metal layer thickness [nm, µm] of an applied layer or the resistivity [mOhm·cm] of the substrate. The software records a line profile that provides an insight into the quality of the coating or substrate. Different designs for common coating chambers such as Endura available.

The interconnection module is typically used for:

- Upgrade of existing deposition systems with measurement capabilities

- Enhanced instant quality control

- Line profile of sheet resistance, metal layer thickness and resistivity

- Predictive maintenance

Sensor Capabilities

- Sheet Resistance [0.01 – 1,000 Ohm/sq]

- Metal Layer Thickness [5 nm – 2 mm]

- Resistivity [0.1 – 100 mOhm·cm]

- Wafer Temperature

Gap Size

5 – 50 mm (depending on wafer handler)

Supported Substrates

150 – 300 mm Wafer

Supported Interfaces

- UDP

- PROFINET

- TDP

- .Net libraries

- Modbus (upcoming)

- EtherCAT (upcoming)

Supported Sizes

- 150 mm

- 200 mm

- 300 mm

Features and Benefits

Enables Measurement on

Process Wafers

Instant Feedback

Within Deposition Chamber

Higher Deposition Quality Through Enhanced Run-to-run-control

Optimize Target Lifetime

Faster Recipe Setting For New Targets / Faster Tool Ramp-up

Higher Throughput

Through Less Test Wafer

Savings Because of No Test Wafers Sample Monitoring

Instant Process Data For Out-of-spec wafer

Available Interfaces

- UDP

- PROFINET

- TDP

- .Net libraries

- Modbus (upcoming)

- EtherCAT (upcoming)

Analyzing Options

- Line profile of sheet resistance, metal layer thickness, resistivity

- Instant deposition data for new material configurations

- Wafer-to-wafer and first wafer effects

- Chamber-to-Chamber effects

- Data for run-to-run control

- Effects of target lifetime

Video of the EddyCus® inline ICM

The video gives you an impression of how to use the interconnection module. Which materials can be analysed and how the device works in general.

Data Table for EddyCus® inline ICM

System Features

| Measurement technology | Non-contact high frequency eddy current sensor |

| Place of measurement | In-vacuo installation between handling area and slit valve |

| Substrates | Wafer, glass, etc. |

| Measurement gap size | 5 – 50 mm (depending on wafer handler) |

| Module sizes | 150 / 200 / 300 mm |

| Conductive layers | Metals, alloys and other conductive layers |

| Environment | In-vacuo @ T up to 220 °C / 428 °F |

| Sample rate | 1 / 10 / 50 / 100 / 1,000 measurements per second for line scan |

| Hardware trigger | 5 / 12 / 24 V |

| Interfaces | UDP, TCP, Rest-API, Modbus, Profinet, analog/digital |

Measurement Capabilities

| Sheet Resistance Measurement | |

|---|---|

| Sheet resistance measurement range | 0.001 – 1,000 Ohm/sq (depending on the gap size) | Metal Layer Thickness Measurement |

|

Thickness measurement of metal films (e. g. Cu, Al, Ag, Au, Ni, Ti, Ta, Pt, W) |

5 nm – 2 mm (in accordance with sheet resistance) | Resistivity Measurement |

| Thickness measurement range | In accordance with sheet resistance |

Frequently Asked Questions

Sheet resistance, metal layer thickness, resistivity,