Battery Cells and Stacks

Control Drying, Thickness & Conductivity in Battery Electrode Production

Consumer electronics, automotive, stationary and industrial applications require highly efficient energy storage solutions. Battery cell manufacturers have to ensure excellent quality while addressing high troughput specifications and finally maximizing the uptime of the equipment. Coating processes have to monitored, especially for manufacturing of:

- Current collectors

- Electrodes

- Anodes

- Cathodes

- Separators

- Electrolytes

Testing

- Sheet resistance

- Conductivity

- Functionalization

- Thickness

- Homogeneity

- Area weight

- Drying status

- Areal capacity

- Porosity

Applications

- Deposition process control

- Drying process control

- Calandering process control

- Welding process control

- Quality control

Substrates

- Metal foil (Cu, Al)

- Plastic foil (BOPP)

- Wafer

- Mesh

- Non-woven

- Ceramics

Processes

- S2S

- R2R

- Wafer level

Environment

- In-vacuo and ex-vacuo

- In-situ and ex-situ

- Inline and offline

- Wet and dry

Cathode Materials

- NMC (NCM) – Lithium Nickel Cobalt Manganese Oxide (LiNiCoMnO2)

- LFP – Lithium Iron Phosphate (LiFePO4/C)

- NCA – Lithium Nickel Cobalt Aluminium Oxide (LiNiCoAlO2)

- LMO – Lithium Manganese Oxide (LiMn2O4)

- LNMO – Lithium Nickel Manganese Spinel (LiNi0.5Mn1.5O4)

- LCO – Lithium Cobalt Oxide (LiCoO2)

Anode Materials

- Graphite

- Amorphous carbon

- Activated carbon

- Carbon black

- Conductive additives

- Graphene

Use Case Electrodes

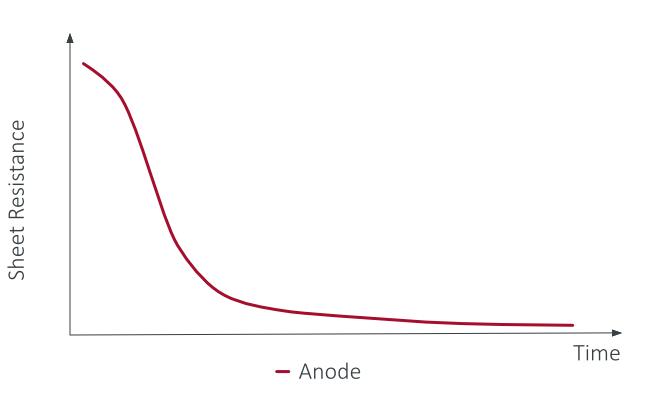

Drying Status

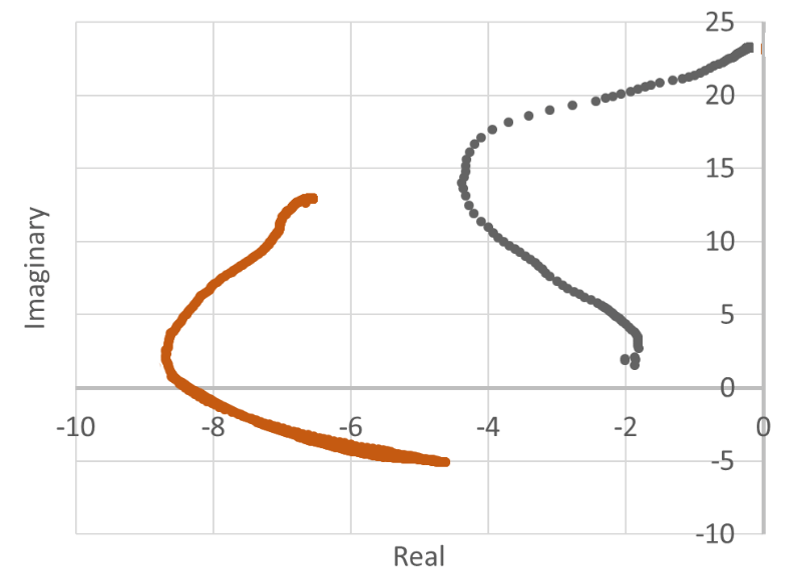

Areal Capacity

Drying status over time as well as areal capacities of electrode ink or pastes deposited on substrates were derived by complex eddy current impedance.