Elektrische Anisotropy Measurement

Content Overview

Table of Contents

Electrical Anisotropy Measurement by Eddy Current

The measurement of electrical anisotropy by eddy current anisotropy sensors allows the precise measurement the anisotropy strength and anisotropy direction without sample preparation or even contacting the test object. The key of this innovation is the induction of directed eddy currents into thin films and the subsequent determination of directed sheet resistances by electromagnet field (EMF) sensors. Anisotropy sensors and instruments save a tremendous amount of time since a measurement can be done in milli-seconds. Further benefits include

- No sample preparation

- Non-contact & non-destructive

- Measurement through encapsulation

- Determination of anisotropy strength

- Determination of anisotropy direction

- High repeatability and accuracy

- Large anisotropy measurement range 0.25 to 4 (MD / TD, larger on request)

This technology is applied in industrial applications since 2015. The dedicated EddyCus SR-A series includes single point, imaging and inline devices. Those systems determine the directed sheet resistance in two or four directions and present the data as numbers, graphical bars or as anisotropy images.

Terminology – What is Electrical Anisotropy?

Definition

The available definitions of electrical anisotropy are often addressing the background of its application. The general definition of electrical anisotropy describes the variation of an electrical property depending on the lateral or vertical direction (x,y,z) in which is a current flows. In other words, the term “electrical anisotropy” describes the directional dependence of the electrical conductivity or resistivity or other electrical terms such as sheet resistance or carrier mobility. The scale of anisotropy can be microscopic or macroscopic and even be different on small and large scale.

Concept and Terminology of Sheet Resistance Anisotropy

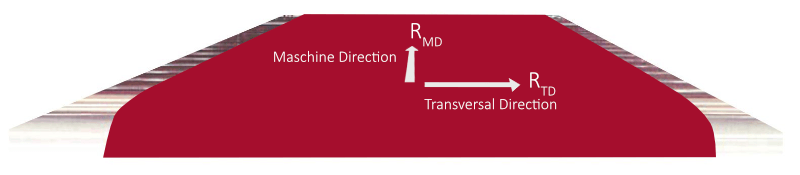

MD = Machine Direction TD = Transversal Direction

RMD = Sheet Resistance in MD RTD = Sheet Resistance in TD

The anisotropy depends on the material, the process type and process parameters. There are isotropic or rather isotropic processes such as PVD or CVD processes. There are also high throughput processes such as slot die coating or curtain coating which generate anisotropy depending on process parameters such as speed or if measures are taken to reduce or increase anisotropy. Furthermore, there are also high anisotropic applications e.g. screen printing in PV industry where the metal meshes structures (fingers) are designed for efficient current transport towards the collectors. An overview in typical anisotropy rations is given here.

| Processes | Calculation |

| Isotropic processes | RMD = RTD |

| Anisotropic processes |

RMD < RTD RTD / RMD = 1.0 – 1.2 or 1.2 – 2.0 |

| Forced anisotropic processes (e.g. by mesh design) |

RMD << RTD RTD / RMD = 2 – 200 (and higher) |

Calculation of Sheet Resistance Anisotropy

The relevant directions for anisotropy calculation are the minimum (Rdirection min) and the maximum (Rdirection max) sheet resistance direction. Most inline manufacturing processes tend to align the wires into machine direction when transferring wire or tube material onto moving web. Therefore, the best or minimum sheet resistance is present in machine direction. Consequently, the worst or highest sheet resistance is achieved into the traversing direction.

Rdirection max = RTD Rdirection min = RMD

Generally, the best sheet resistance direction Rdirection min is perpendicular to worst sheet resistance Rdirection max.

Rdirection max = Rdirection min + 90 degree Rdirection min = Rdirection max + 90 degree

There are two common ways to describe anisotropy. Either the ration between the lowest and highest sheet resistance is taken. An alternative way is the description of the difference of both directions divided by the average.

Relative Anisotropy = RTD / RMD Anisotropy [%] = (RTD – RMD) / ((RMD + RTD) · 0,5)

Electrical Anisotropy in Transparent Conductive Materials.

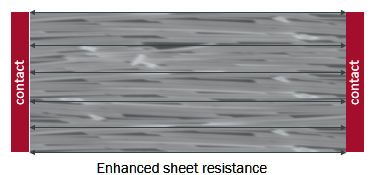

Transparent conductive materials excel in electrical conductivity and in optical transparency at the same time. The challenge for TCM manufactures is that the electrical resistance can be improved by adding more material which is then worsening the transparency. Many companies compete for providing the best sheet resistance to transparency ratio. Nanowire, tube and mesh structure are able to provide outstanding SR to OT rations at good costs. There are some cases where the conductivity of a film is directed to the electrodes which results in even better SR to OT rations. The key points of this concept are shown here:

Anisotropic Wire Film

- Anisotropy can be optimized according to the layout of the contact pattern

- Anisotropy can save material and improve optical transparency

- Anisotropy can be measured in non-contact mode by EddyCus TF inline anisotropy sensor

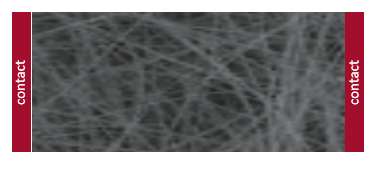

Isotropic Wire Film

- More of the conductive (and non-transparent) material is required in order to sufficiently supply this structure with current

Types of Tools for the Measurement of the Electrical Anisotropy

Benchtop Tools

for Single Point Measurements

Our handheld systems are ideal for quick, spot-check measurements—whether at goods receipt, during in-process inspection, or for large-format components where fixed setups are impractical.

Simply place the handheld unit on the surface to be measured, press the “Measure” button, and within one second, the measurement value appears on the display.

Each reading represents the precise value at the measurement point—giving you rapid, reliable feedback wherever you need it.

Imaging Tools

for Full Area Images

Our technology delivers highly detailed, full-surface information about product quality—enabling meaningful conclusions about process quality and stability. This data supports targeted optimization of both the manufacturing process (e.g., resource efficiency, throughput speed) and the product itself (e.g., improved homogeneity, compliance with minimum specifications).

For measurement, the sample is placed centrally on the measurement field. Prefabricated holders—such as those for wafers—ensure precise, centered positioning. Simply insert the sample, close the flap, and press “Start Measurement.”

The result: a high-resolution false-color map of the entire layer, generated from thousands of individual measurement points. This visualization gives you actionable insights at a glance.

Inline Systems

for Continuous Single Point Measurements

Our inline systems enable continuous acquisition of data on both process quality and product characteristics—before, during, or after a production step. This real-time monitoring is a foundation for production automation, which relies on precise and reliable sensor data.

The system is seamlessly integrated into your existing production line. Once the operator initiates measurement, all data is automatically recorded and stored in a centralized database.

Depending on the system configuration, the output includes one or more line profiles—either centered or positioned at critical points across the layer—providing clear insight into quality trends and process stability in real time.

Measurement of Electrical Anisotropy

The measurement of the resistivity anisotropy may expose insights about the material structure and scattering processes in anisotropic and low-dimensional materials. Its anisotropy is affected by the geometry of conductors, its connection, the number contact points and length paths and the effective parallel resistances.

A difference in lateral (y,x) sheet resistance / resistivity / conductivity within a material or film can be measured by contact or non contact testing methods. Contact methods require the cut out of narrow and long material sections in a ration of 1 : 20 (eg. 1 cm x 20 cm). Here the direction of the cutout describes the direction measurement. The sheet resistance can be measured by contact measurement after applying contact pad to the material film. The nature of this setup results in the disadvantage that a measurement on the same position is not possible. The layout of possible cut outs is shown at the right.

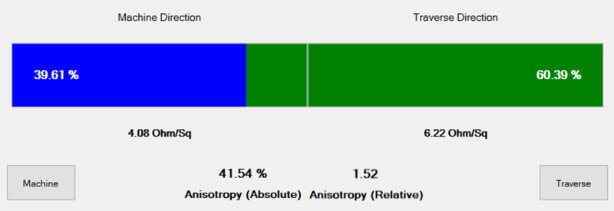

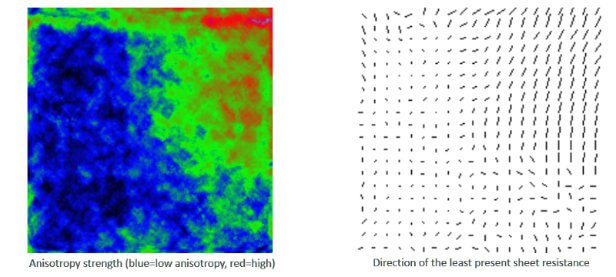

Non-contact measurement of electrical anisotropy is done by SURAGUS Eddy Current anisotropy sensors. Those are especially designed to induce currents in defined directions such as MD = Machine Direction | TD – Transversal Direction. There are single point measurement systems and imaging measurement systems proving in detail information on anisotropy strength and direction across the entire sample. Examples for sheet resistance anisotropy depiction are shown below. The first images shows the individual sheet resistances RMD and RTD and the absolute and relative calculated values. The right image depicts the anisotropy distribution across a sample where blue represents anisotropic areas and red anisotropic areas. The black and white line image depicts the anisotropy strength as length of the lines where dots represent isotropic areas and long lines anisotropic areas. The direction of anisotropy is exposed by the direction of a line.

Single point / inline

Single Point Anisotropy Evaluation with Eddy TF lab 2020A Series

Imaging

Anisotropy Image of Spray Coated Silver Nanowires.

Testing Devices for Anisotropy Measurements

Industry and R&D laboratories have different requirements according to number of measurement samples per day, measurement point density and automation level. In result, four key testing types are commonly applied

- Handheld

- Laboratory / Benchtop

- Single point

- Imaging

- Inline / Tool integrated

- Inline static single / multi-sensor