Fuel Cell Components

Automotive, stationary and industrial applications require highly efficient energy conversion solutions. Fuel cell manufacturers have to ensure excellent quality while addressing high troughput specifications and finally maximizing the uptime of the manufacturing equipment. Process monitoring and quality control is required for manufacturing of:

- Catalyst coated membrane (CCM)

- Gas diffusion layer (GDL)

- Gas diffusion electrode (GDE)

- Membrane electrode assembly (MEA)

- Bipolar half plates

- Bipolar plates (BPP)

Testing

- Sheet resistance

- Conductivity

- Thickness

- Homogeneity

- Area weight

- Drying status

- Areal capacity

- Catalyst loading

- Porosity

Applications

- Molding process control

- Deposition process control

- Drying process control

- Calandering process control

- Decal transfer control

- Quality control

Substrates

- Graphite

- Carbon

- Stainless steel

- Membranes

- Meshes

- Fluoropolymers

Processes

- S2S

- R2R

Environment

- In-vacuo and ex-vacuo

- In-situ and ex-situ

- Inline and offline

Materials

- Inks

- Pastes

- Graphite

- Amorphous Carbon

- Catalysts

- Platinum

- Cobalt

Types

- Alkaline fuel cells (AFC)

- Polymer electrolyte membrane fuel cell (PEM)

- Direct methanol fuel cell (DMFC)

- Phosphoric acid fuel cell (PAFC)

- Molten carbonate fuel cells (MCFC)

- Solid oxide fuel cells (SOFC)

Use Case Electrodes

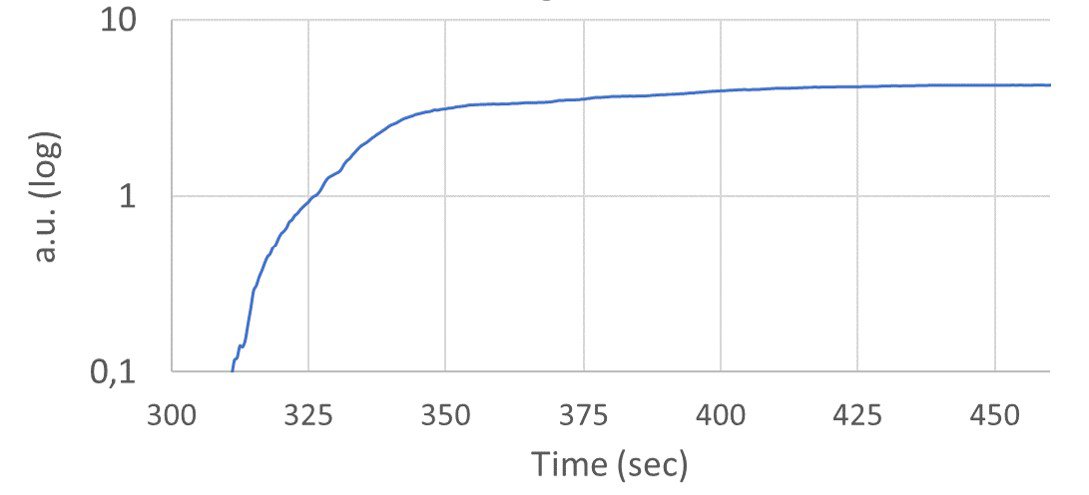

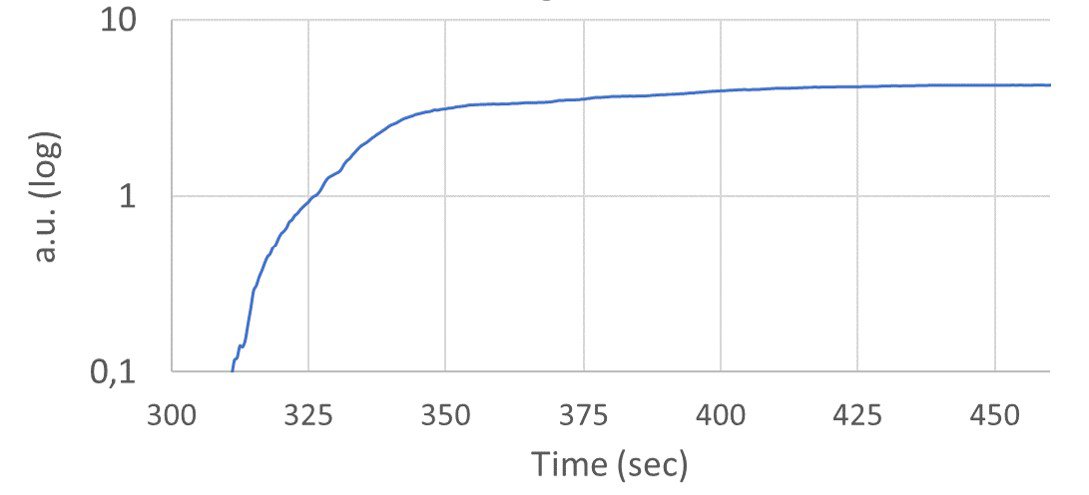

Drying Status

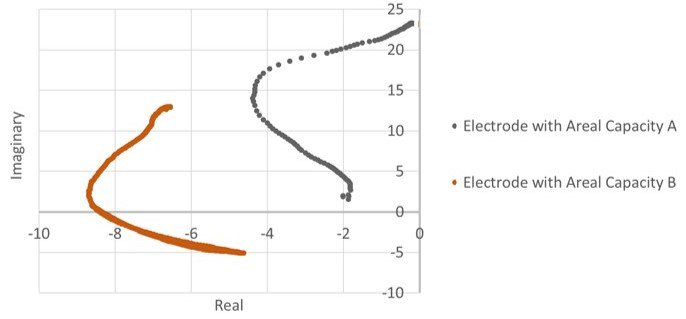

Areal Capacity

Drying status over time as well as areal capacities of electrode ink or pastes deposited on substrates were derived by complex eddy current impedance.

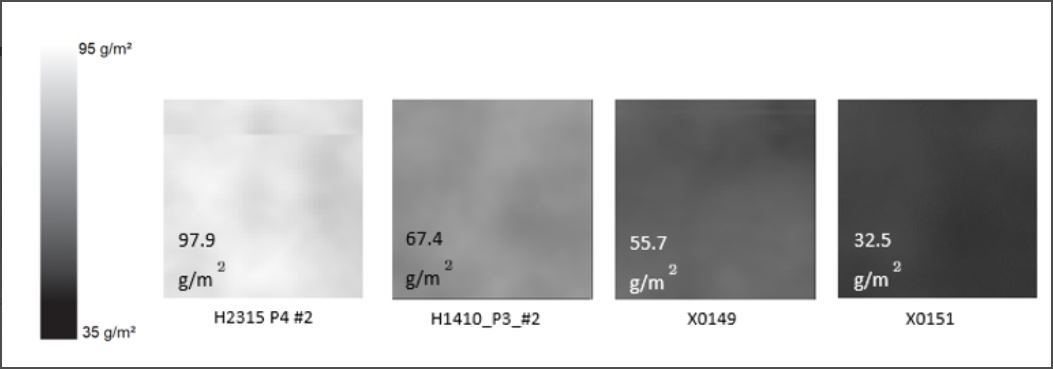

Use Case Carbon Non Woven Gas Diffusion Layer for PEM

Areal Weight

Due to the anisotropic behavior of carbon fiber filaments high frequency eddy current technology enables characterization of carbon non woven gas diffusion layer for PEM fuel cells.

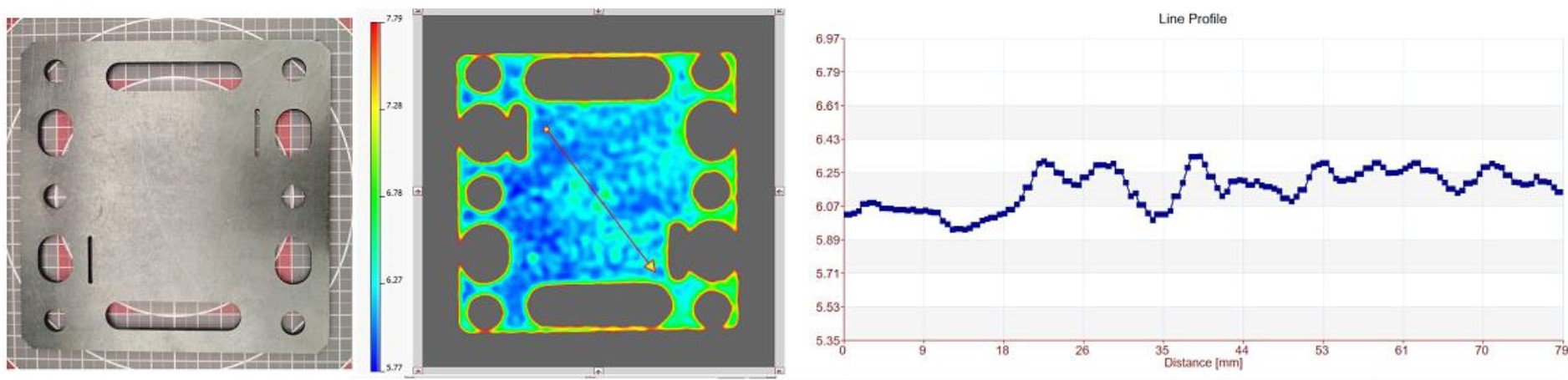

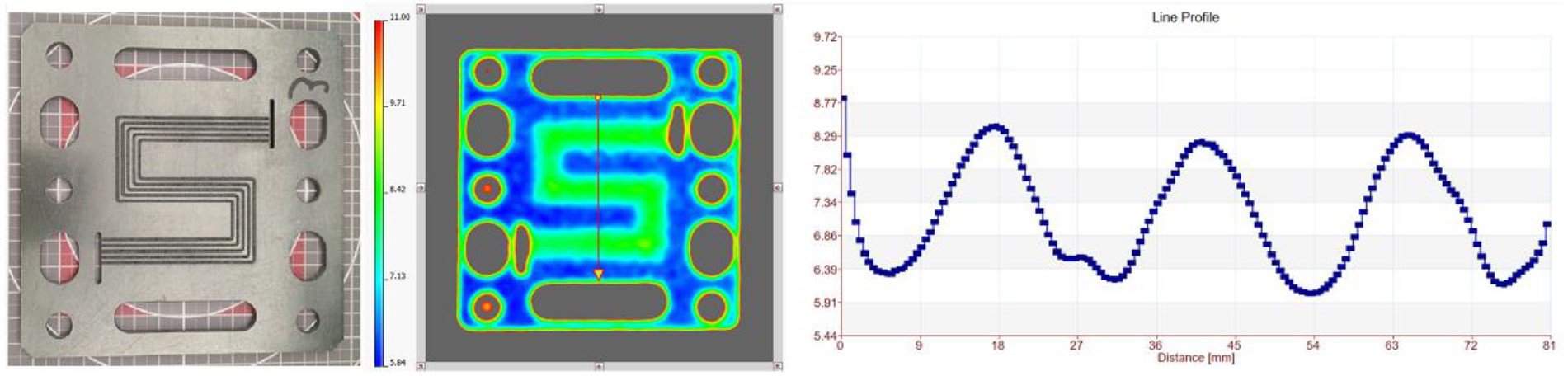

Use Case Carbon Based Bipolar Plates

Sheet Resistance

Sheet resistance of bipolar half plate bulk material is characterized by high frequency eddy current imaging solutions. The carbon plate bulk material was kindly provided by the Open Source Stack initiative of the Innovation Cluster HZwo e.V.. Flow field water jet cutting process was applied by NOVAJET GmbH.