Handheld Device For Measuring Conductive Layers Or Substrates

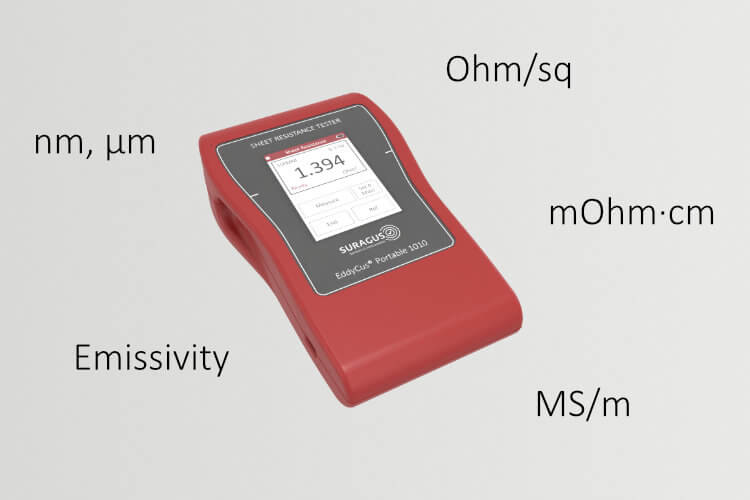

Parameters: Sheet Resistance · Metal Layer Thickness · Resistivity · Conductivity · Emissivity

Non-destructive testing using eddy current technology – fast, accurate, and ready for on-site quality control.

- Small and portable measurement device

- Measurement of hidden layers

- Manual measurement

- Instant live measurement

- Digital data collection and data transmission via Bluetooth

- Characterization of hidden and encapsulated conductive layers

Introduction

The EddyCus® portable 1010 is a handy and portable measurement device for fast contact measurement of large glasses and foils in production or in the field, for example for quick quality checks after manufacturing or as incoming good inspection. The handheld device allows the measurement even of hidden and encapsulated layers. It is an easy-to-use device that is controlled via a touch display.

Features and Benefits

Wireless Data Transfer

Up to 9h Operation Time

Touch Display

Digital Data Collection

Quick Check with

Instant Values

< 3 % Accuracy

< 1.5 % Repeatability

Large Substrates Measureable

> 150 mm x 150 mm

Digital Data

Management

One Device, Multiple Measurement Parameters

The EddyCus® portable is capable of measuring multiple parameters. Sheet resistance correlates with metal layer thickness, emissivity, and resistivity. As long as the material properties are well known, all of these parameters can be measured with high precision.

- Sheet resistance

- Metal layer thickness

- Resistivity

- Conductivity

- Emissivity

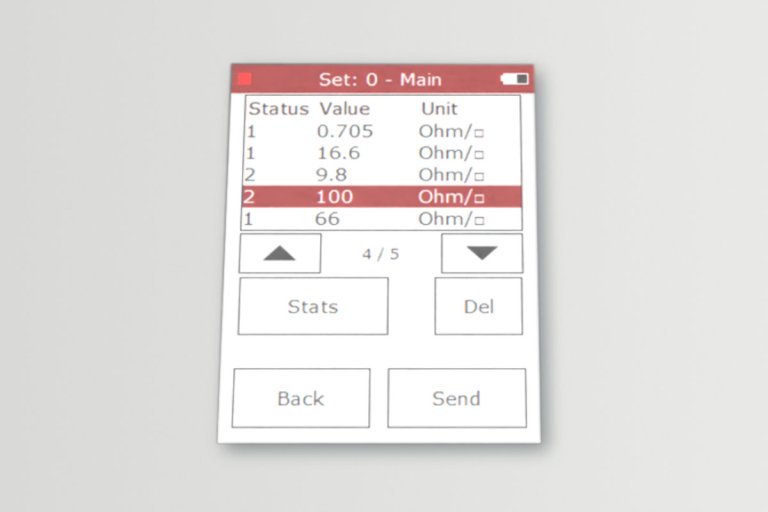

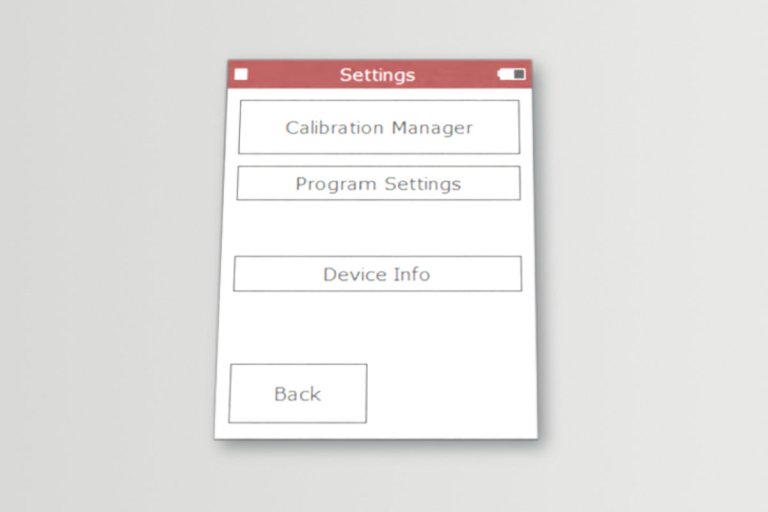

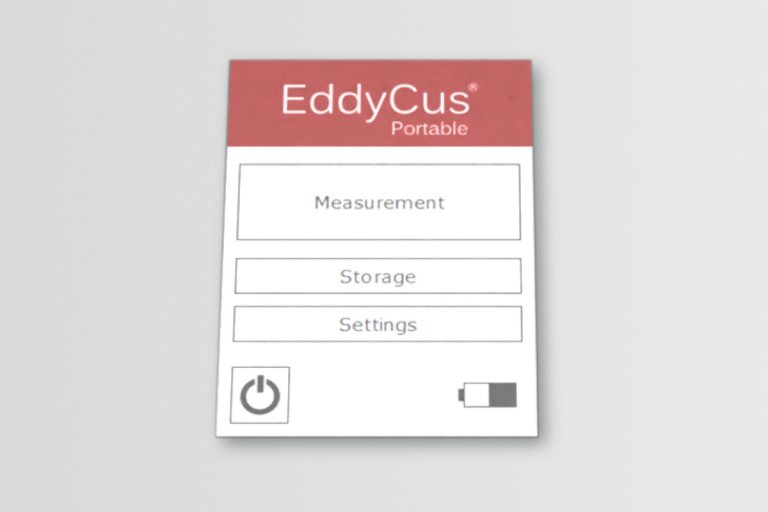

Software and Device Control

The intuitive software interface allows users to quickly select a predefined recipe and initiate a measurement with a single click. Results are displayed in under one second.

- User-friendly user interface

- Touch display

- Digital data tracking

- Long battery lifetime (approximately 9 h in continuous operation)

- Instant measurement of sheet resistance and correlated properties such layer thickness and emissivity and data aggregation

- Bluetooth interface

Video of the EddyCus® portable

The video gives you an impression of how to use the Portable. Which materials can be analysed and how the device works in general.

Areas of Application

In general, eddy-current technology is employed to inspect and characterize conductive materials and conductive coatings such as conductive foils, coated foils or coated glass and other applications.

Data Table for EddyCus® portable

| Measurement technology | Eddy current sensor |

| Measurement mode | Realtime at constant distance / contact |

| Substrates | Glass, foils, etc. |

| Substrate sizes | Flat samples > 150 mm x 150 mm (6 inch x 6 inch) Curved editions are available for several applications (windshields, etc.) |

| Measurement spot / high sensitivity zone | 40 mm diameter (1.6 inch) |

| Power | Lithium ion battery up to 20 h |

| Display | 2.8 inch colored touch screen |

| Device dimensions (w/h/d) @ weight | 3.5” x 7” x 1.9” / 87 mm x 178 mm x 48 mm @ 340g |

| Interfaces | Bluetooth (optional) + data center |

EddyCus® portable – Measurement Capabilities

| Sheet Resistance Measurement | ||||||||||||||||||||||||||

| Sheet resistance range |

Low: 0.001 – 10 Ohm/sq Std: 0.3 – 100 Ohm/sq |

|||||||||||||||||||||||||

| Accuracy | Better 3 % | |||||||||||||||||||||||||

| Repeatability | Better 1.5 % | |||||||||||||||||||||||||

| Emissivity Measurement | ||||||||||||||||||||||||||

| Emissivity range | 0.003 – 0.1 | |||||||||||||||||||||||||

| Metal Layer Thickness Measurement | ||||||||||||||||||||||||||

|

||||||||||||||||||||||||||

| Resistivity Measurement | ||||||||||||||||||||||||||

| Resistivity range |

Low: 0.0025 – 0.015 mOhm·cm Std: 1 – 300 mOhm·cm |

|||||||||||||||||||||||||

| Accuracy | Better 3 % | |||||||||||||||||||||||||

| Repeatability | Better 1.5 % | |||||||||||||||||||||||||

| Conductivity Measurement | ||||||||||||||||||||||||||

| Conductivity range for metals and alloys | 0.01 – 65 MS/m | |||||||||||||||||||||||||

| Conductivity range for SiC | 0.003 – 0.03 MS/m | |||||||||||||||||||||||||

| Conductivity range for Si, GaN, GaAs | Upon request | |||||||||||||||||||||||||