Easy to Use and Highly Customizable Software for Inline Process Monitoring

The SURAGUS Suite is a software for EddyCus® inline Systems to make monitoring and evaluation of data fast an easy. It is developed to simplify process and product monitoring.

- Intuitive, fast and easy – all important data at a glance

- Touch operable

- Fully customizable charts

- Real time display of measurement data

- Fully addressable and high speed database

- System automation via UDP interface

Introduction

Inline monitoring systems can be implemented into MES or other high level manufacturing software. SURAGUS offers independ sensor systems using comprehensive software.

- Direct implementation of sensors using .Net libraries (documentation, project examples, sensor mockup are provided pre setup and test)

- Data transmission via standardized protocols (e.g. Modbus) or TCP/IP based protocols

- Data access via OPC by KEPServer with ODBC client

- Analog or digital communication via I/O module(s), individual parameterizable

- Data access via database mapping

- Additional solutions on request

SURAGUS provide three software solutions:

- The EC inline Control software is a self developed analysis tool

- The OEM and developer kits is a SDK and data post processing SDK that allows you to design a customized software for the specific needs accordung to your business

- Direct PLC integration to control the manufactoring process

EC inline Control Software

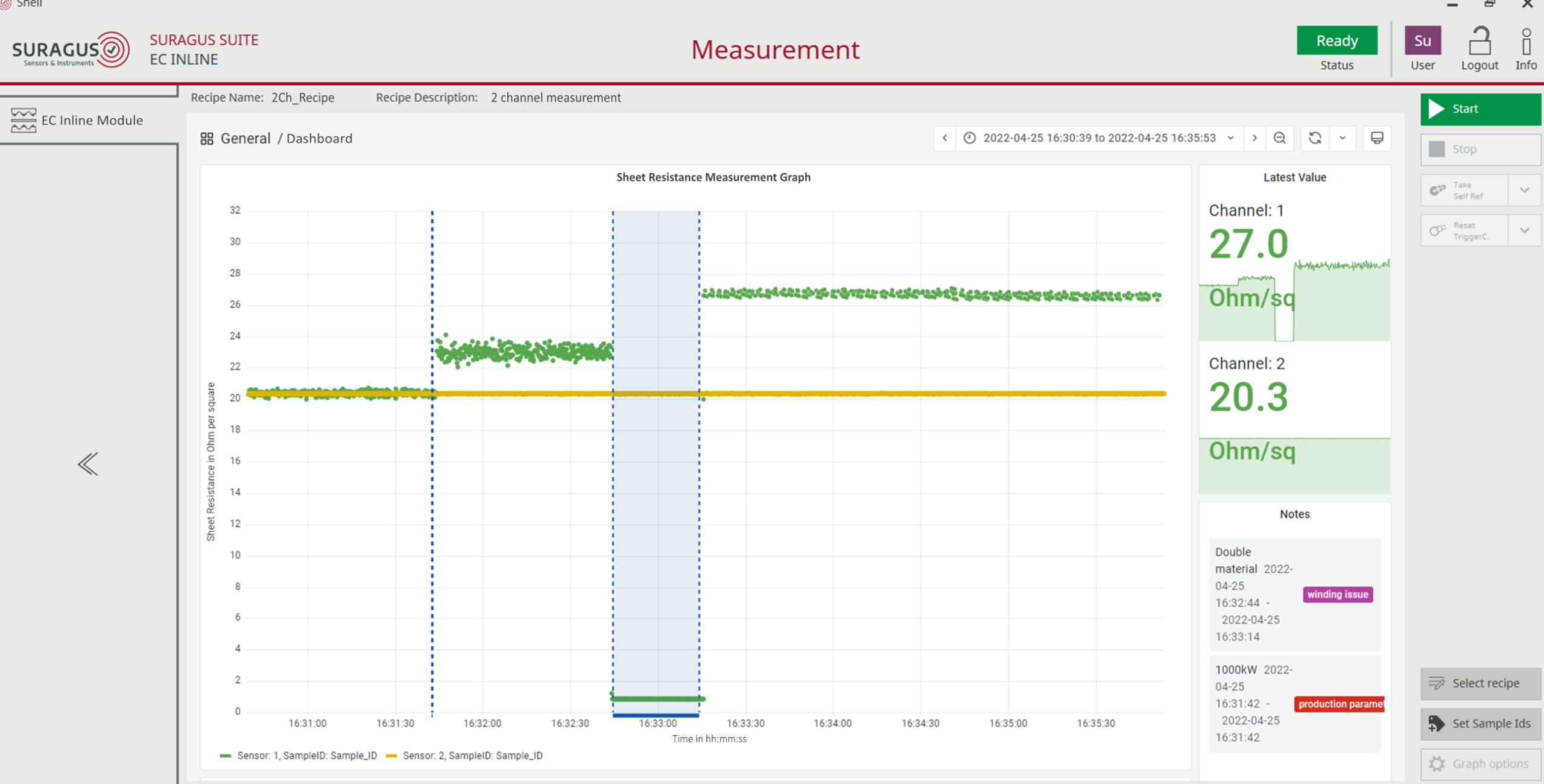

- Graphical live view (different time windows, from 1 minute to 24h)

- Analysis view (data selection from database, statistics)

- Sorting by time, distance, roll number, barcode or Data Matrix code.

- Mode for extending and adapting the calibration

- Parameterization dialog of I/O modules for analog and digital data transmission as well as the parameterization of alarms in case of over/underrun of threshold values

- Automatic and manual data export (csv, txt, xls, …)

- Automatic database cleaning

Fully Customizable GUI

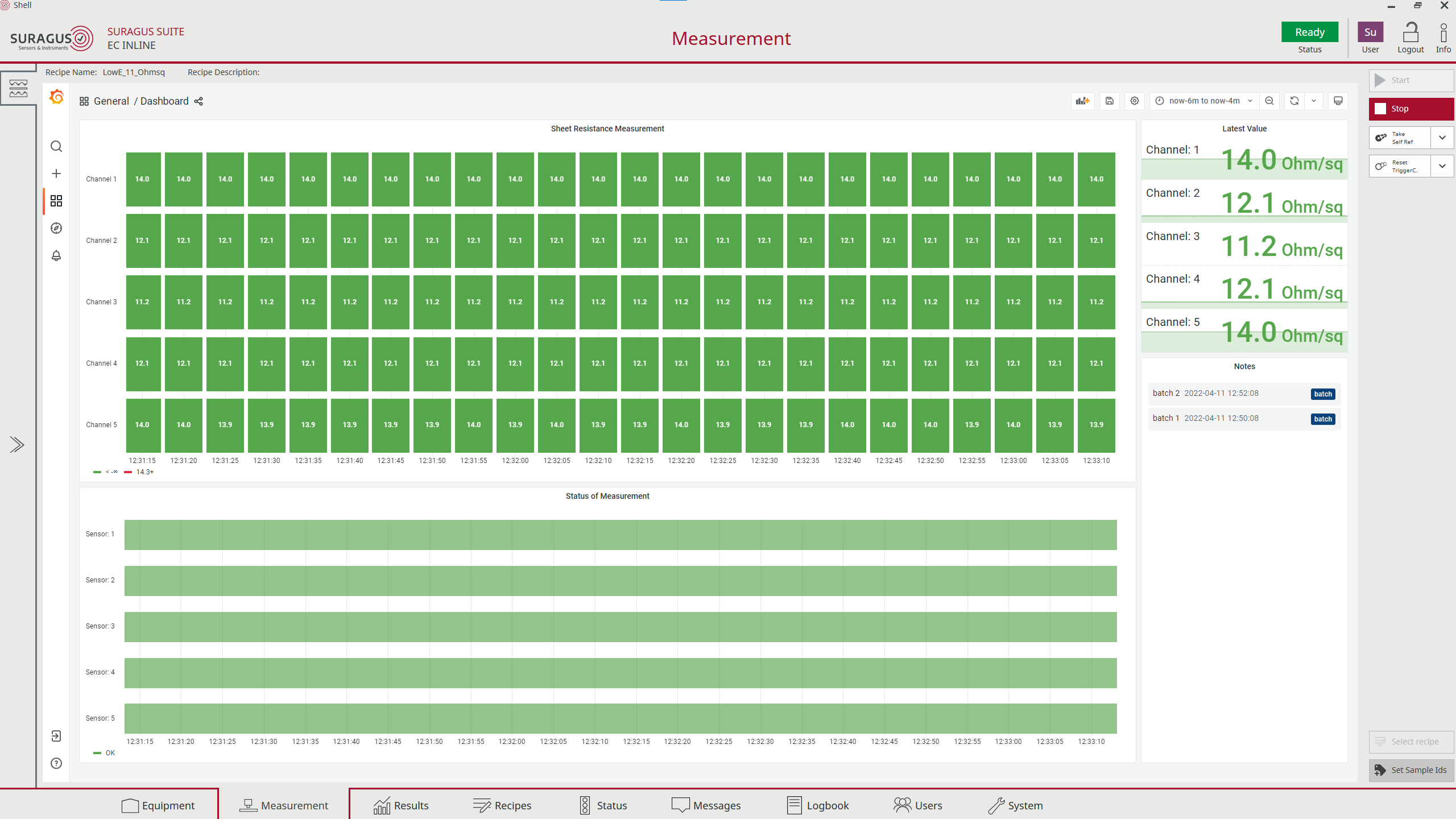

Grafana allows you to fully customize your data view to your needs. You can personalize the display of the measurement results with the help of 22 graph options. A heatmap is a product driven view and a good choice to visualize the quality of a wide object with multi sensor lanes like a glass or foil production process. If you prefer statistics you can also choose a histogram. So you can see the quality of the process from a statistic point of view.

You have a lot of options and you can combine them to create the view you need for your optimal workflow.

Direct PLC Integration

SURAGUS offers serveral hardware options for PLC integration incl. sensors with full digitalization at sensor level and direct PLC communicaton.

- Interfaces

- Modbus

- UDP

- TCP XML

- Profinet

- OI module

- Trigger mode

- Free Running

- Gate Mode (high / low)

- Edge Mode (raising / falling)

- One Measurement on High / Low

- Other points

- User and roll management