Conductive Slurry and Paste Testing Solutions for Process Control

Higher process and material quality through fast and precise Inline Measurement

based on non-contact eddy current technology.

- Quality assurance

- Process control

- Yield improvement

- Customer trust by documented spool / roll report

Introduction

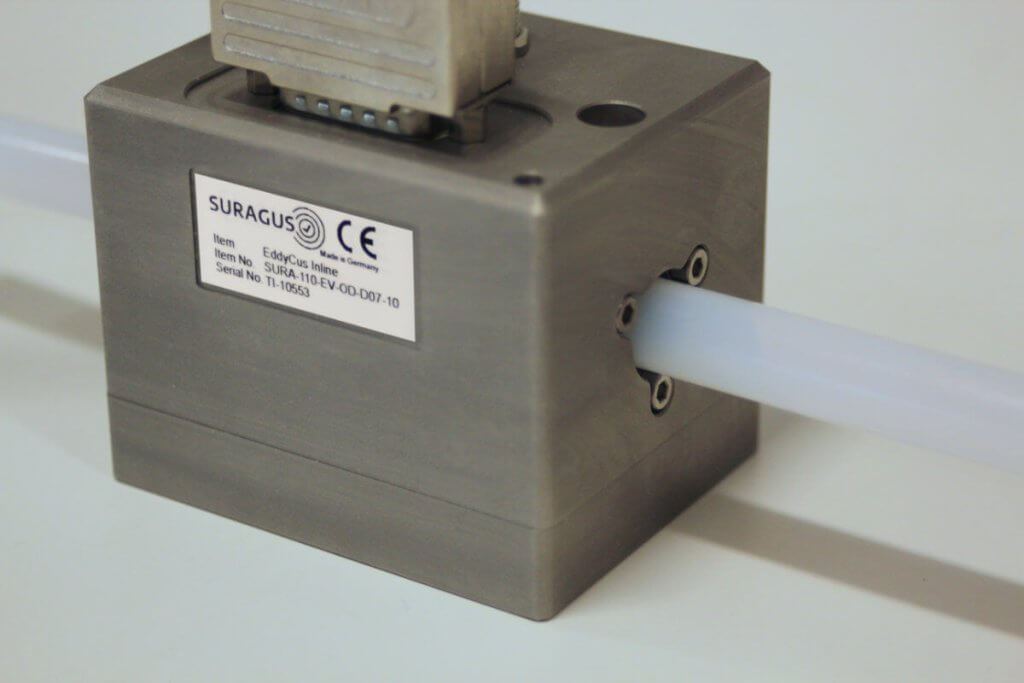

The EddyCus® Inline R series is an annular sensor engineered for non-contact, continuous inline testing of any conductive material passing through a tube. The sensor features a standard opening diameter of 12 mm, with custom sizes up to 90 mm available on request. This solution supports advanced process control, yield optimization, and reliable inspection of incoming and outgoing goods.

The device is typically used for:

- Conductive pastes, slurries and fluids

Sensor Capabilities

Supported Substrates

Tubes with 3 – 12 mm diameter (up to 90 mm on request)

Optional Temperature Sensor

Features and Benefits

Up to 200 Sensors

Single-lane and Multi-lane Solutions

High Production Speed up to 10 m/s

Feed Data Directly to a PLC

Contact Free and Real Time

Accurate Measurement

Slurrys, Pastes and Inks

- Composition is defined by recipe (e.g. active material, carbon black, binder, graphite)

- Structure of components depends on mixing processes (dry, wet)

- Particle size, volume fraction, viscosity, morphology

- Slurry characteristics affect on downstream processes

- Coating (thickness, layer density)

- Spatial distribution of active material in through-plane direction

- Drying behavior (diffusion paths, porosity)

- Calendering behavior

- Post-Calendering drying

- Filling with Electrolyte

- Coating (thickness, layer density)

- Mixing quality affects on battery performance

- Energy density

- Defects (particle breakage)

Slurrys and Pastes Measurement Tasks

- Permittivity

- Conductivity

- Homogeneity

- Moisture

- Areal capacity

- Areal weight

- Viscosity

- Sheet resistance

Inline Setup

- Sensor integration into slurry production/ mixing lines

- Integration of 1 or more sensors at different stages of slurry flow

- Measurement of conductivity of slurry, solvent composition, particle size, mixing quality

- Maximum pipe size is 20 mm (up to 100 mm on request)

- Real time high-speed measurement

Software

- Several views and user level

- Live view with upper and lower limits and alarm functions

- Analysis view providing statistics

- Can handle data of several thousands measurements per second

- Data storage into SQL database

- Customizable automated data export (csv, txt, xls,…)

- Several smart functions (automated DB cleaning, self-reference etc.)

- Parameterizable I/O modules (triggering of actions or alarms)

Measurement Speed

- 0.1 Hz to 50 kHz suitable for up to 50 m/s movements

Geometry

- Tubes with diameter 0.01 to 10 mm (other on request)

Applications

Liquid Characterization & Classification

- Fluid identification

- Viscous liquid sorting

- Emulsion and suspension analysis

- Contamination detection

- Blend verification

Flow Process Monitoring & Control

- Real-time mixing monitoring

- Dilution control

- Phase separation detection

- Reaction progress tracking

- Crystallization monitoring

Paste & Viscous Material Applications

- Paste consistency control

- Slurry concentration measurement

- Gel formation monitoring

- Coating material quality

- Cement and mortar monitoring

Pipeline & Flow System Monitoring

- Multiphase flow analysis

- Batch boundary detection

- Flow regime identification

- Leak detection

- Cleaning verification

Food & Beverage Flowing Products

- Liquid food quality

- Sauce and condiment monitoring

- Dairy processing

- Brewing and fermentation

- Cooking oil management

Chemical & Pharmaceutical Liquids

- Drug solution concentration

- Solvent purity monitoring

- Chemical feed streams

- Cleaning solution effectiveness

- Waste stream characterization

Industrial Fluid Applications

- Hydraulic fluid condition

- Coolant management

- Lubricant analysis

- Heat transfer fluid monitoring

- Fuel quality assessment

Advanced Flow Applications

- Microfluidics monitoring

- Spray characterization

- Foam quality control

- Biofluid analysis

- Environmental flow monitoring

Process-Specific Flowing Material

- Continuous coating processes

- Injection molding

- Extrusion monitoring

- Pumping efficiency

- Storage tank management

Data Table for EddyCus® inline R

System Features

| Measurement technology | Non-contact high frequency eddy current sensor |

| Test material geometry |

Diameter: 3 – 12 mm Other on request (up to 90 mm on request) |

| Substrates | Pastes, inks, plastics, composites, ceramics, resins, liquids, etc |

| Sensor type | Open / closed loop |

| Number of sensor pairs / monitoring lanes | 1 – 99 |

| Other integrated measurements | Metal thickness / optical transmittance / density / anisotropy |

| Measurement range | Depends on measurement task, please contact our team |

| Accuracy | Depends on measurement task, please contact our team |

| Environment | Ex-vacuo, T < 60°C / 140°F (higher on request) |

| Sample rate | 1 / 10 / 50 / 100 / 1,000 measurements per second |

| Hardware trigger | 5 / 12 / 24 V |

| Interfaces | UDP, .Net libraries, TCP, Modbus, analog/digital, and others |

Measurement Capabilities

| Sheet Resistance Measurement | |

|---|---|

| Measurement types |

Line resistance (Ohm/m), sheet resistance (Ohm/sq) Resistivity / Conductivity Shielding quality / electrical impedance Coating uniformity (electric and magnetic) |

| Line resistance range | 0.5 mOhm/m – 500 Ohm/m |

| Sheet resistance range | 0.001 – 250 Ohm/sq | Metal Layer Thickness Measurement |

| Measurement types |

Metal thickness of coatings (nm, µm) Wire thickness (µm, mm) Shielding quality, coating uniformity |

| Metal thickness range | 0.005 – 5,000 µm | High Frequency Measurement |

| Sheet resistance range | 0.01 – 1,000 Ohm/sq; 1 – 5 % accuracy |

| Anisotropy range (TD/MD) | 0.33 – 3 (larger upon request) |

| Materials |

Nanowires Nanotubes / Nanobuds Regular metal meshes Materials with egg shaped domains Stacked multilayer systems with advance current transport functions |

| Measurement Results |

Absolute / relative anisotropy Dominant current transport directions Sheet resistance in machine direction Sheet resistance in traversing directions (cross-web) |

Wet Coating and Residual Moisture Measurement |

| Measurement types |

Wet coating thickness Residual moisture Composition monitoring (electric, dielectric, magnetic) |

| Wet coating thickness range | 10 – 5,000 µm |

| Residual moisture range | 5 – 1,000 % |

Frequently Asked Questions

Sheet resistance, metal layer thickness, resistivity, wet coating thickness, residual moisture, composition monitoring (electric, dielectric, magnetic)