EddyCus® inline SLIM – Smart Link Integrated Module

Use existing gates and link transfers: equip them with a measurement add-on to generate early-stage measurement data.

- Non-contact and non-destructive

- Near-process monitoring

- High-speed and accurate

- High repeatability and long term stability

- Test directly on product wafers

- Easy integration into tools

Whats is a Smart Link Integrated Module (SLIM)?

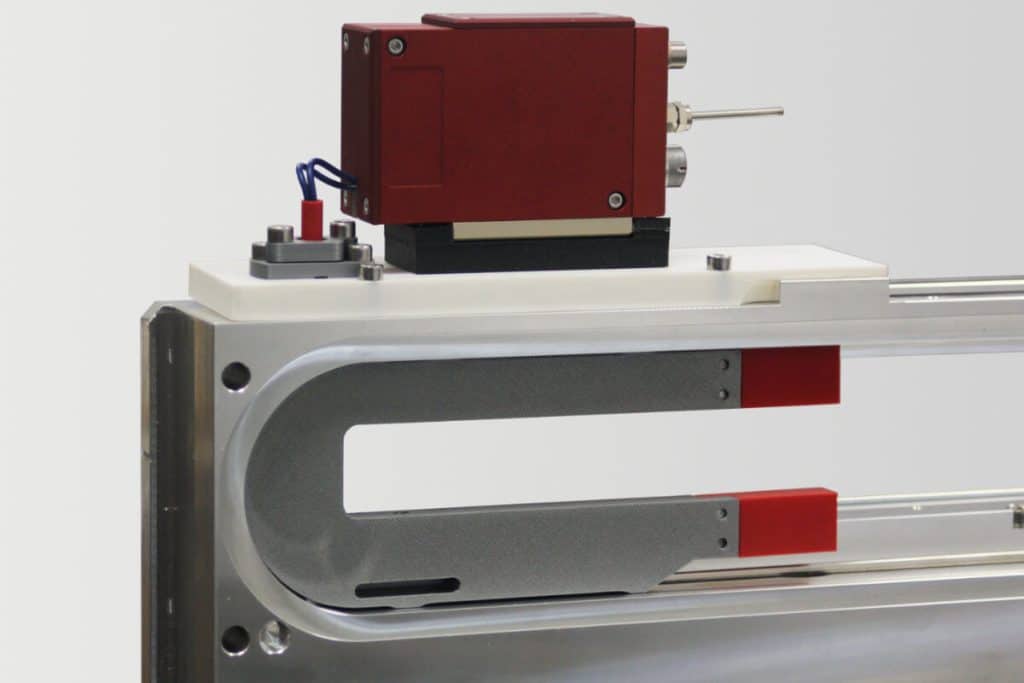

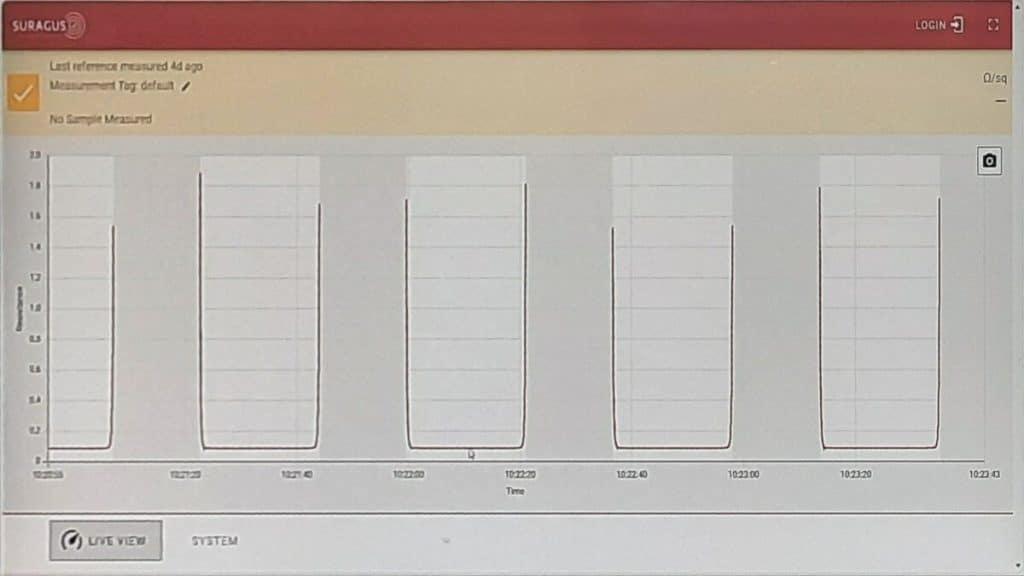

The EddyCus® inline SLIM is a non-contact eddy-current measurement add-on for deposition tools. It is integrated directly at vacuum interfaces such as gate valves, ports, or transfer links. The system generates line profiles before and after deposition, providing immediate feedback at the point of interest.

This enables fast reaction times and allows you to significantly reduce or even completely eliminate the use of test wafers. With continuous measurement data over time, target wear and degradation become clearly visible.

The tool is equipped with two non-contact eddy-current sensors operating in transmission mode. This setup provides high-resolution information on the homogeneity of the substrate material and conductive coatings, even across sensor gaps of up to 50 mm.

The tool is typically used for:

- Sheet resistance from 0.001 – 1,000 Ohm/sq,

- Metal layer thickness of a thin film from 5 nm – 2 mm,

- Resistivity 0.1 – 100 mOhm·cm,

- Temperature sensor available

- Total thickness from 300 – 1,500 µm and

- Bow from ± 2 mm.

Sensor Capabilities

- Sheet Resistance [0.001 – 1,000 Ohm/sq]

- Metal Layer Thickness [5 nm – 2 mm]

- Resistivity [0.1 – 100 mOhm·cm]

Integration Points

Semi-conformal in-vac feedthroughs such as

- Valves

- Ports

- Links

Supported Substrates

- 150 mm,

- 200 mm and

- 300 mm wafer

(Si, SiC, etc.)

Data Extraction

Data transmission runs through a dedicated lid

with a vacuum rated feedthrough that

connects the sensor to the control unit

Supported Interfaces

- UDP

- TCP

- Rest-API

- Modbus

- Profinet

- Analog/digital

Features and Benefits of Tool Integrated Inline Monitoring System – EddyCus® inline SLIM

2 – 12 Inch Wafer

Non-contact Top and Bottom Side

Line Profile Analyzing

Multi-Parameter Measurement

Reduces Need for Test Wafers

Early Detection of Process Drifts

Easy to Use

No Additional Space for

Testing Equipment Required

Easy Retrofit Without Re-qualification

Installing the EddyCus inline SLIM is quick and non invasive. The existing valve lid is replaced by a lid with an opening for the cable feedthrough. The deposition tool remains in place and keeps its qualification.

Simple retrofit workflow

- Remove the original cover

- Remove the valve

- Insert the sensor fork into the wafer transfer path

- Mount the valve again

- Route the cable through the prepared opening

- Install the replacement cover with cable feedthrough to the control unit

- System is ready for measurement

Typical installation time is within one hour.

Direct Process Control Inside Chamber

for the Reduction of Test Wafer

Eddy current in-tool measurement transforms vacuum deposition from a periodic, test-wafer-driven process into a continuous, data-driven, self-monitoring system. By providing real-time thickness feedback on actual production wafers, it:

- Shortens qualification cycles

- Reduces measurement latency

- Minimizes uncertainty

- Cuts the need for dedicated monitor and test wafers

As a result, fabs achieve higher throughput, lower cost of ownership, and significantly reduced non-productive wafer usage, while maintaining or even improving process stability and uniformity.

Eddy current and four point probe measurements correlate closely.

Click here to see a detailed comparison.

Data Table for EddyCus® inline SLIM

System Features

| Measurement technology | Non-contact high frequency eddy current sensor |

| Place of measurement | In-vacuo installation within valve or link |

| Substrates | Wafer, glass, etc. |

| Measurement gap size | 15 – 50 mm (depending on wafer handler) |

| Module sizes | 150 / 200 / 300 mm |

| Conductive layers | Metals, alloys and other conductive layers |

| Environment | In-vacuo @ T up to 220 °C / 428 °F |

| Sample rate | 1 / 10 / 50 / 100 / 1,000 measurements per second for line scan |

| Hardware trigger | 5 / 12 / 24 V |

| Interfaces | UDP, TCP, Rest-API, Modbus, Profinet, analog/digital |

Measurement Capabilities

| Sheet Resistance Measurement | |

|---|---|

| Sheet resistance measurement range | 0.001 – 1,000 Ohm/sq (depending on the gap size) | Metal Layer Thickness Measurement |

|

Thickness measurement of metal films (e. g. Cu, Al, Ag, Au, Ni, Ti, Ta, Pt, W) |

5 nm – 2 mm (in accordance with sheet resistance) | Resistivity Measurement |

| Resistivity measurement range | In accordance with sheet resistance |

Request a Quote

You can use the formular to write us a message.

Frequently Asked Questions

- Sheet resistance

- Metal layer thickness

- Resistivity

- 150 mm,

- 200 mm and

- 300 mm samples

- 2 – 4 inch wafers via adapters

- Sheet resistance line profile

- Metal layer thickness line profile

- Resistivity line profile