Wafer Characterization

Semiconductor wafer substrates must meet strict specifications for resistivity, homogeneity, and structural integrity before they enter device fabrication. High-frequency eddy current technology provides a fast, contact-free method for characterizing bare and processed wafers — delivering the data needed to qualify incoming material, monitor crystal growth and wafering processes, and ensure substrate quality at every stage of the supply chain.

Testing Options in Wafer Characterization

Sheet Resistance

Wafer Resistivity

Wafer Thickness

Wafer Homogeneity

Permeability

Defectoscopy

Facette Formation

Wafer Bow & Warp

Electrical Anisotropy

Applications for Wafer Characterization

Incoming Wafer Inspection

Before wafers enter device fabrication, incoming inspection verifies that the substrate material meets the required resistivity range, thickness tolerance, and homogeneity specifications. Eddy current measurement performs this check rapidly and without risk of surface damage, catching out-of-spec wafers before costly processing begins.

Wafer Imaging & Near Edge Monitoring

Wafer Process Monitoring

Wafer Quality Control

Wafer Deposition Process Control

Pre- and Post-Treatment Process Control

Typical Wafer Substrates

Silicon (Si)

| Diameter | Typical Thickness | Resistivity Range | Typical Applications |

|---|---|---|---|

| 100 mm (4″) | 525 ± 25 µm | 0.001 – 100 Ω·cm | MEMS, R&D, sensors |

| 150 mm (6″) | 675 ± 25 µm | 0.001 – 10,000 Ω·cm | Power devices, RF (FZ) |

| 200 mm (8″) | 725 ± 25 µm | 0.005 – 100 Ω·cm | IC, analog, MEMS |

| 300 mm (12″) | 775 ± 25 µm | 0.005 – 50 Ω·cm | Advanced logic, memory |

Silicon Carbide (SiC)

| Diameter | Typical Thickness | Resistivity Range | Typical Applications |

|---|---|---|---|

| 100 mm (4″) | 350 ± 25 µm | 0.01 – 0.05 Ω·cm (n-type) | R&D, legacy power devices |

| 150 mm (6″) | 350 ± 25 µm | 0.01 – 0.05 Ω·cm (n-type) | SiC MOSFETs, diodes, EV inverters |

| 150 mm (6″) | 500 ± 25 µm | > 10⁵ Ω·cm (semi-insulating) | RF, microwave, 5G |

| 200 mm (8″) | 525 ± 25 µm | 0.01 – 0.05 Ω·cm (n-type) | Next-gen power electronics |

Gallium Nitride (GaN)

| Substrate Type | Typical Diameter | Typical Thickness | Resistivity Range |

|---|---|---|---|

| Native GaN (free-standing) | 50 – 100 mm | 350 – 400 µm | 0.01 – 0.05 Ω·cm (n-type) |

| GaN-on-Si | 150 – 200 mm | 675 – 1,150 µm | Depends on Si carrier |

| GaN-on-SiC | 100 – 150 mm | 350 – 500 µm | Semi-insulating SiC carrier |

| GaN-on-Sapphire | 50 – 150 mm | 330 – 650 µm | Insulating carrier |

Sapphire (Al₂O₃)

| Diameter | Typical Thickness | Resistivity | Typical Applications |

|---|---|---|---|

| 50.8 mm (2″) | 330 ± 25 µm | Insulating (> 10¹¹ Ω·cm) | R&D, small-format LEDs |

| 100 mm (4″) | 500 – 650 µm | Insulating | LED epitaxy, optical windows |

| 150 mm (6″) | 650 ± 25 µm | Insulating | High-volume LED production |

Wafer Characterization Across Process Steps

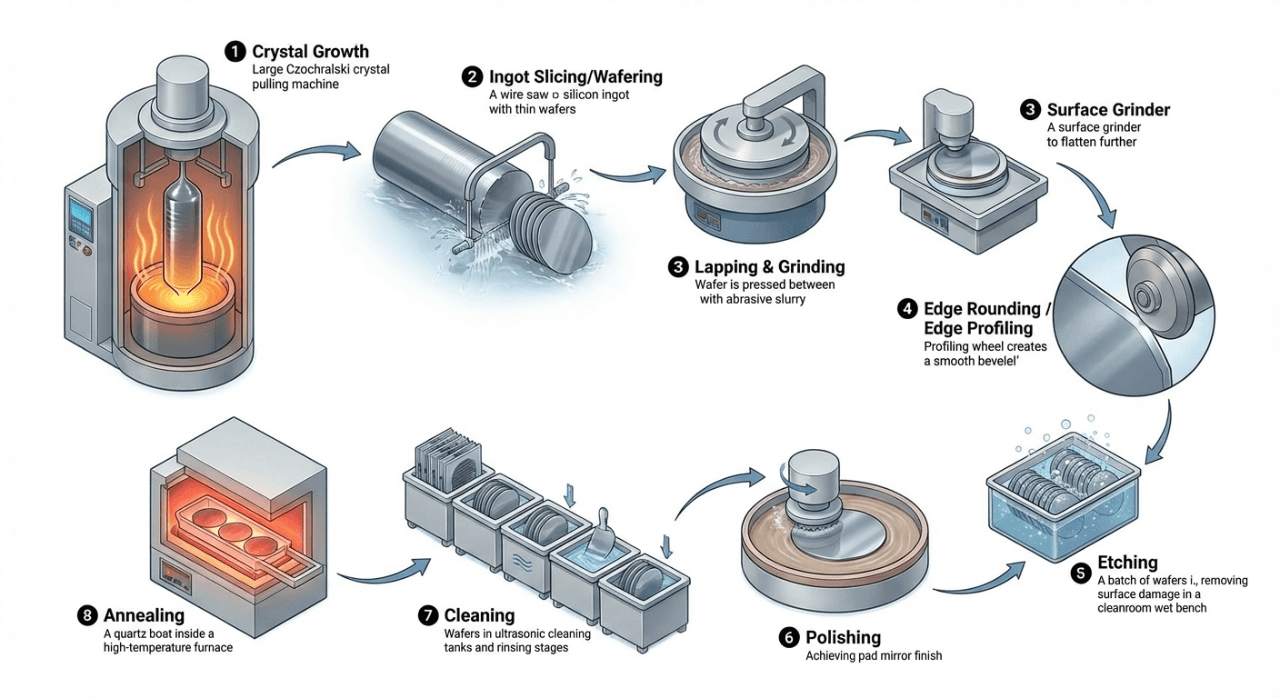

Wafer manufacturing involves a series of precisely controlled process steps — from crystal growth to final polishing. Eddy current wafer characterization can be applied between or during these steps to verify substrate quality, detect process-induced changes, and provide real-time feedback for optimization.

Crystal Growth

Ingot Slicing / Wafering

Lapping & Grinding

Edge Rounding / Edge Profiling

Edge grinding and profiling shape the wafer rim to prevent chipping and improve handling in automated equipment. While this step primarily affects geometry, eddy current near-edge measurements can verify that the edge treatment has not introduced localized resistivity changes or micro-damage in the peripheral zone of the wafer.

Etching

Chemical etching removes the remaining sub-surface damage layer left by lapping and grinding. Depending on the etchant and process parameters, etching can also affect surface resistivity and wafer geometry. Eddy current wafer characterization before and after etching quantifies the material removal and verifies that the substrate’s electrical properties remain within specification.

Polishing (CMP / SSP / DSP)

Cleaning

Annealing

Why: Qualify crystal doping & uniformity before committing to wafering

Why: Detect saw-induced variations for early sorting & grading of as-cut wafers

Why: Verify target thickness is reached & material removal is even across wafer

Why: Quantify etch removal & confirm electrical properties remain in spec

Why: Last quality gate — confirms wafer meets all specs before shipment or epitaxy

Why: Detect residual metallic contamination that cleaning may have missed

Why: Verify dopant activation & confirm target resistivity profile is achieved

Wafer Characterization Integration

Wafer Level

Batch Systems

Load Lock

Cluster Systems

Inline

Environment

Eddy current wafer characterization adapts to the full range of measurement environments encountered in semiconductor wafer manufacturing — from vacuum chambers to atmospheric offline stations.

In-Vacuo and Ex-Vacuo

In-Situ and Ex-Situ

Inline and Offline

Inline wafer characterization is embedded in the material flow and enables 100% substrate inspection in production. Offline wafer characterization is performed on sampled wafers at a dedicated station — ideal for in-depth analysis, process development, correlation studies, and customer qualification.

Wafer Characterization by Device Type

Eddy current wafer characterization supports a broad spectrum of semiconductor device segments — ensuring that the starting substrate meets the specific requirements of each end-use application.